Background:

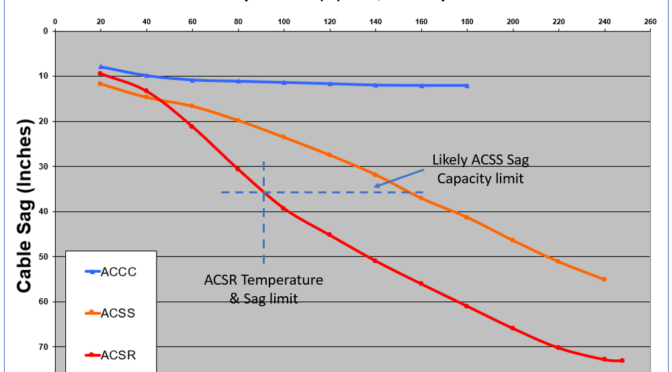

Bare overhead aluminum conductors reinforced by steel core wires (ACSR conductors) have been used since the early 1900’s to transmit and distribute electrical energy. As higher levels of energy are transmitted, the conductor’s electrical resistance causes the wires to heat up, stretch, and sag. Because the conductive aluminum strands in ACSR conductors weaken if operated at temperatures above 93° C, manufacturers in the 1970’s developed ACSS conductors. ACSS conductors used pre-annealed aluminum that could operate at temperatures up to 200° C, but the overall strength of ACSS conductors was about 25% lower than ACSR conductors. In the 1980’s manufacturers used higher strength steel cores to improve the overall strength of ACSS conductors and, over time, introduced improved corrosion barriers that could allow ACSS conductors to operate at temperatures up to 250° C. While higher operating temperatures enable increased electrical capacity, higher operating temperatures also equate to substantially higher I2R line losses which negates much of the higher capacity benefit. Because the coefficient of thermal expansion of steel remains unchanged, the thermal sag exhibited by ACSS conductors is also substantially higher than ACSR conductors when operated at higher temperatures. It is also noteworthy that the core temperature of ACSS conductors when operated at their upper limits can be as much as 50° C hotter than the outer conductive aluminum strands which further exacerbates excessive sag and can damage the protective corrosion resistant coatings.

In the early 2000’s CTC Global developed and commercialized the ACCC® Conductor that uses a hybrid carbon and glass fiber core to replace the steel core used in ACSR and ACSS conductors. The coefficient of thermal expansion of the ACCC Conductor’s composite core is ~ten times lower than steel which mitigates thermal sag. The composite core is also 70% lighter than steel which enables the use of ~30% more aluminum without an overall weight or diameter penalty. The added aluminum content reduces electrical resistance and helps deliver more power with 25 to 40% lower line losses. Reduced line losses reduce fuel consumption and associated greenhouse gas (GHG) emissions (including CO2), while also freeing-up generation capacity otherwise wasted. Considering that thermal power plants use an average of 12,000 gallons of clean, filtered, and pumped water to produce 1 MWh of electricity, reducing line losses can also reduce freshwater consumption and further contribute to lowering the overall cost of wholesale electric energy.

Key Benefits of ACCC® Conductor over ACSS Conductor:

1. The ACCC Conductor’s composite core mitigates thermal sag.

- Reduced sag reduces the chance of sag/trip power outages as occurred during the major east coast blackout of 2003.

- Reduced sag improves safety – keeping people and equipment at safer distances.

- Reduced sag improves clearances to vegetation to reduce risk and impact of wildfires.

2. The ACCC Conductor core is stronger than steel core.

- Higher strength enables greater spans between fewer and/or shorter structures to reduce construction costs, construction timeframes, and environmental impact.

- Higher strength ACCC Conductor enables greater design flexibility for structure / pole placement in varied agricultural, industrial, mountainous, or residential environments.

- The ACCC Conductor’s higher strength core is also impervious to corrosion, cyclic load fatigue, and impact damage which reduces maintenance costs and improves resilience.

- The ACCC Conductor’s smooth trapezoidal aluminum strands and composite core dissipate wind-induced Aeolian vibration about ten times more efficiently than conventional round steel and aluminum strands which enables the ACCC Conductor to be installed at higher initial tensions to take full advantage of the conductor’s higher strength.

3. The ACCC Conductor’s improved efficiency offers numerous benefits.

- The ACCC Conductor’s improved efficiency reduces fuel consumption and operating costs to reduce delivered energy and consumer costs.

- Reduced GHG emissions can help utilities and project financiers achieve their sustainability goals.

- Improved efficiency can help deliver more power from less generation resources, while improving the economic viability of renewable generation assets.

4. The ACCC Conductor is ideally suited for reconductoring projects.

- ACCC conductors of the same diameter and weight can be used to replace existing ACSR and ACSS conductors without the need to modify or replace existing structures.

- Increasing the capacity of an existing ACSR line with ACSS conductors generally requires larger heavier conductors that require new or substantially modified structures, which increase costs, construction timeframes, and permitting challenges.

- ACCC Conductors, with proper substation capabilities, can double the capacity of existing lines quickly without the need for substantial permitting – at a fraction of the cost of alternative solutions.

Summary:

The transition from legacy ACSS conductors to modern ACCC® Conductors represents a significant advancement in electrical transmission technology. The ACCC Conductor’s innovative composite core addresses key limitations of older systems, including thermal sag and line losses, while enhancing strength and resilience. This results in safer, more efficient power delivery with reduced environmental impact. By enabling utilities to maximize capacity and reduce costs without extensive infrastructure changes, ACCC Conductors are well-suited for the demands of contemporary energy transmission. As utilities strive for sustainability and efficiency in an evolving energy landscape, adopting ACCC Technology will play a crucial role in meeting these goals while ensuring reliable service for consumers.

CTC Global:

Working in association with over 50 conductor and hardware manufacturers, CTC Global, the developer and manufacturer of the ACCC Core have provided over 185,000 km of ACCC Conductor to more than 300 utility and industrial customers for over 1,300 projects in 67 countries. For more information, please visit www.ctcglobal.com.