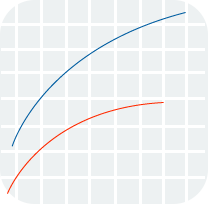

We’re All About Performance and Proof

Extensive testing paved the road to the commercialization and success of the high-performance ACCC® Conductor.

We work with our customers, industry organizations, leading test labs, and universities worldwide to raise the performance bar for bare overhead conductors, validation and longevity testing, and composite core technology. We envisioned the possibilities, aimed high, and created the advanced conductor market.

PRODUCT DEVELOPMENT TESTING

In 2003, CTC Global began the process of optimizing the ACCC® Conductor design by testing numerous core designs, resin formulations and processing techniques. At that time, much of our lab work was outsourced to local labs, a local university and Kinectrics lab, in Toronto, Ontario, Canada. In 2004 we were able to do our first conductor installation at EPRI’s outdoor test facility in Haslet, Texas. Our progress was shared with EPRI’s HTLS Conductor Study participants, which included SCE, EDF, AEP and many other prominent utilities. Product Development Testing, that followed many existing and standardized test protocols, helped us reach and confirm the ACCC® Conductor’s and conductor core performance objectives.

LONGEVITY TESTING

In addition to confirming the tensile, flexural, tortional, thermal and other performance aspects of the ACCC® Core, ACCC® Conductor, and ACCC® Hardware, longevity tests were also performed to ensure the ACCC® Technology could withstand the harsh environmental conditions it would be subjected to over its 40 to 50+ year anticipated service life. As with Product Development Testing, much of the testing (conducted at that time by many other entities throughout the world as well) used industry accepted and standardized test protocols. Because the use of composite materials in bare overhead conductors was novel, many new test protocols were also developed by CTC Global and other entities such as EPRI, AEP and EDF.

PRODUCT VALIDATION & TYPE TESTING

Over the years as ACCC® Technology continues to improve and CTC Global’s product line continues to expand, any changes or new designs are subjected to complete Validation Testing before the products are commercialized. This is much like ‘starting over.’ The entire barrage of tests are performed to assess and confirm product performance and longevity. Type Testing is also performed on every new conductor design and size and/or for utilities that have special requirements and/or that need special documentation. With over 250 utility customers, you can be sure we have plenty of experience. CTC Global’s in-house lab at its facility in Irvine, California, USA is proudly certified to ISO/IES 17025 Standards. If you are in the area, please let us know as we would be delighted to offer you a private tour.

FACTORY ACCEPTANCE TESTING

On nearly a daily basis we host our customers from around the world to witness and document our Quality Assurance Testing on core reels that will be used to produce ACCC® Conductor for their specific projects. This is not a mandatory requirement, but we are happy to comply with special requests.

R&D TESTING

R&D Testing has been running parallel to all of our tests since day one and is listed here to underscore CTC Global’s commitment to advancing conductor technology. We are constantly investing in R&D and R&D Testing to pave the way to the future of overhead conductor technology.

CTC Global’s ISO/IEC 17025 Certified Lab

CTC Global received its Certificate of Accreditation under ISO/IEC 17025 from the prestigious International Accreditation Service (IAS). ISO/IEC 17025 is the international gold standard for independent testing laboratories that confirms CTC Global’s status as the only testing laboratory in the world certified for the full range of tests for composite carbon fiber cores used in bare overhead conductors. This enables CTC Global to fulfill Type Testing requirements and issue Type Test reports to utilities from around the world on a one-stop basis.

CTC Global’s mechanical, physical and chemical test equipment inventory and capabilities are extensive and staffed and operated by a substantial team of scientist, technicians, and experts. CTC Global also has environmental chambers and load frames for full conductor and hardware system testing as well as outdoor structures for full scale conductor testing.

View our certificate. ISO/IEC 17025 >