Background:

In 2003, Composite Technology Corporation – now CTC Global Corporation, introduced the “Aluminum Conductor Composite Core” ACCC® Conductor. Since that time, more than 140,000 kilometers of this product have been installed at well over 1,000 projects, worldwide. The ACCC® Conductor represents the greatest leap forward in overhead conductor technology since the “Aluminum Conductor Steel Reinforced” ACSR conductor was introduced more than 100 years ago.

While CTC Global’s engineering team had vast experience designing, engineering, testing and commercializing high-performance composite technologies for aerospace, automotive and other industrial applications, the introduction of the ACCC® Conductor to the highly risk adverse Utility Industry was no easy task.

CTC began its journey by consulting Asset Managers, Transmission Engineers, Planners, Linemen and others from the Utility Sector to gain substantial insight into their needs, concerns, standards and test requirements. Over the course of several months – and years, CTC Global produced ACCC® Core and Conductor samples that exceed design objectives. Testing began immediately.

Technology:

One of the primary reasons CTC selected carbon fiber as the basis for the ACCC® Conductor Core is because carbon fiber resists cyclic load fatigue about ten times better than steel. Also, it doesn’t plastically deform or yield – under any circumstance. It is also impervious to corrosion. While carbon fiber is about seven times stronger than steel on a per-weight basis, it is fully elastic up to about 2% strain. A unidirectional carbon fiber rod like the ACCC Conductor core, can be pulled to ~98% of its ultimate strength, tens of thousands of times without physical degradation. The ACCC® Conductor also uses a protective layer of high-grade, boron free glass fibers to improve flexibility and toughness – which also serves as a galvanic barrier to protect the conductive aluminum strands wrapped around the core on the finished conductor.

Testing:

While hundreds of tests are performed on the ACCC® Conductor Core (and constituent raw materials) on a daily basis – as part of the Company’s extensive ISO 9001 quality assurance program – and other tests are performed in CTC Global’s ISO/IEC 17025 Certified Laboratory – as the company continues to raise the conductor performance bar and introduce new ACCC® Conductor technologies – Longevity Testing has been ongoing for the last 20 years.

Longevity Testing:

Longevity testing was – and remains – a key component of product acceptance and widespread technology adoption. As mentioned above, carbon fiber itself offers tremendous benefits compared to steel in the application of bare overhead conductors, nevertheless, these products – designed to last decades in very harsh conditions – are subject to many stressors, the impact of which can be understood through extensive longevity testing and computer modeling.

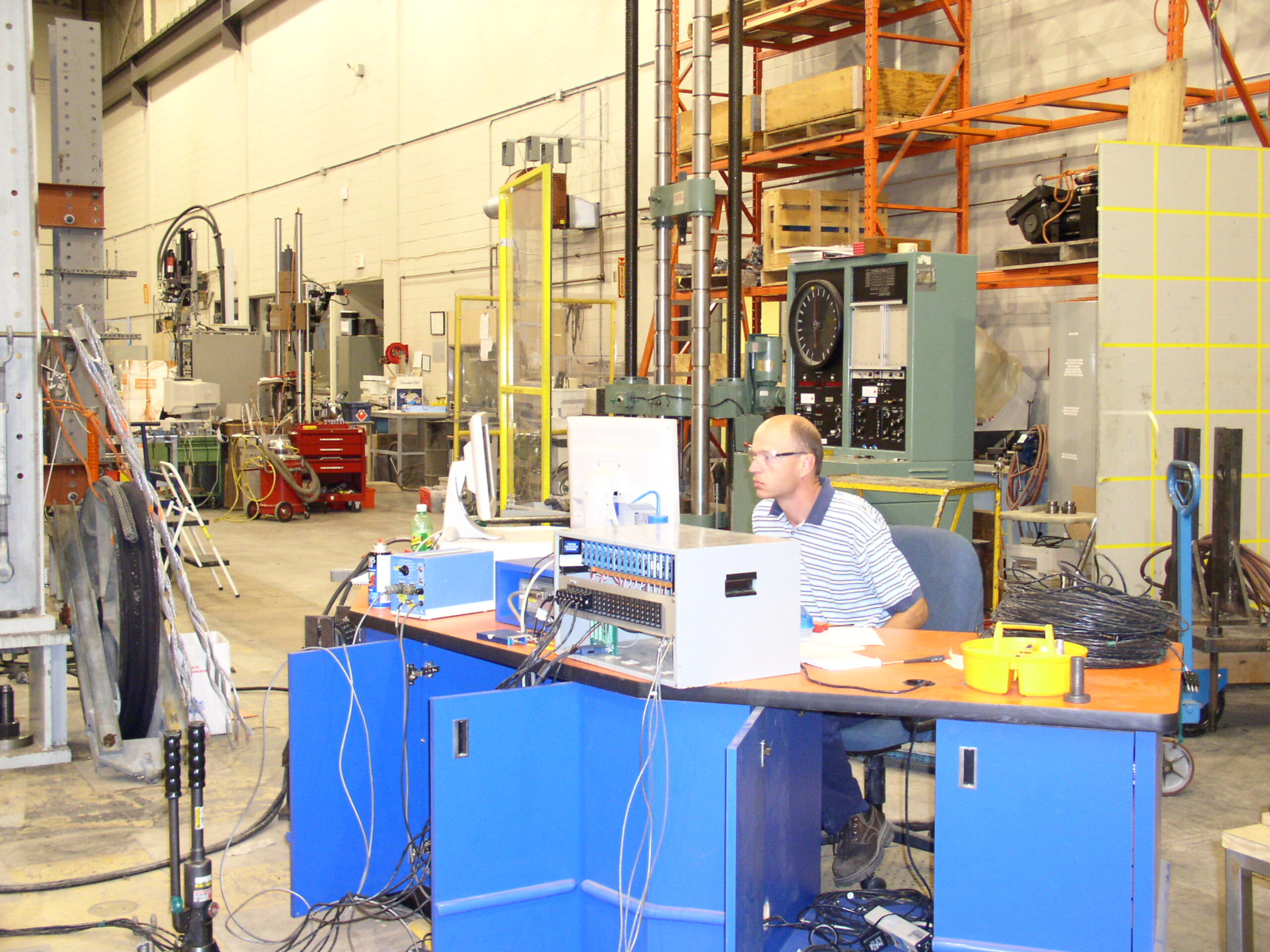

These tests include: Tensile; Flexural; Shear; High Frequency Vibration; Low Frequency Galloping; Thermal Aging; Torsion; Bending; and approximately 75 other highly specific tests – the majority of which follow ASTM, IEEE or other recognized test standards and test protocols.

Figure 1 – Examples of testing conducted on ACCC Conductor and ACCC Core to assess its performance and longevity.

Because the ACCC® Conductor uses a novel composite core, many utilities, international labs and universities developed novel test protocols.

American Electric Power, for example, developed and implemented a “Sequential Mechanical Test” where they subjected ACSR, ACSS (conventional steel reinforced conductors) and ACCC to extreme bending – under tension – to replicate installation stress, followed by 100 million cycles of vibration and 100 thousand cycles of galloping (using certified connectors and suspension clamps). They then pulled the samples to failure. Afterwards, they took the ACCC® Conductor back to AEP’s in-house test lab in Dolan, Ohio and completed another two dozen test protocols on ACCC® Core samples. AEP was highly satisfied and has been very successful installing over 3,700 kilometers of ACCC® Conductor at over 20 projects in the U.S.

EPRI, another well-known industry leader, also performed a series of other novel performance and longevity tests. In addition to lab testing in the U.S., the U.K, France, Canada, Mexico, China, Brazil, Chile, Belgium, Indonesia, and Germany, many University students from around the world also studied and tested various attributes of the ACCC® Conductor and composite core technology as part of their master and doctorate programs. At Denver University, alone, over 30 students tested ACCC® Conductor and core performance and longevity characteristics prior to their graduations.

Other techniques such as Finite Element Analysis conducted by Alpha Star and Arrhenius Aging Tests have confirmed the ACCC® Conductor’s superior performance and longevity. For more information, please email [email protected] or visit www.ctcglobal.com