Following the western energy crisis of 2000 and major east coast blackout of 2003, CTC began the development of the ACCC@ conductor in an effort to increase the capacity of congested transmission lines that were constrained due to thermal sag.

Essentially, CTC Global recognized the numerous advantages of carbon fiber composite materials and developed – and rigorously tested – a composite core that is about 50% stronger and 70% lighter than steel with a coefficient of thermal expansion about 90% less than steel – it does not sag like steel when hot. These outstanding properties have enabled CTC Global to deploy 60,000+ kilometers of ACCC conductor to more than 550 project sites in 50+ countries, since it was first commercialized in 2005.

The globally-patented and trademark-registered ACCC conductor, manufactured in association with 24 cable companies worldwide, uses fully annealed, trapezoidal shaped aluminum strands that offer improved conductivity compared to any other aluminum currently in use today. Coupled with the light-weight carbon composite core, the ACCC conductor offers an increased aluminum content of as much as 30% without a weight penalty. The added aluminum content and quality increase the conductor’s ampacity – or current carrying capability – to about twice that of a conventional conductor, as well as significantly reducing line losses compared to any other conductor on the market today. Line loss reductions can range from 25 to 40% or more depending on load level. The improved efficiency of the ACCC conductor along with its ability to carry twice the current of a conventional conductor- without excessive sag – offers huge advantages.

As those in the aerospace, automotive and many other industries already appreciate, the carbon composite core is highly resistant to environmental aging, will not corrode, and resists degradation from cyclic loading such as from temperature, vibration, tension, and stress cycles.

To date, more than 175 utilities worldwide have begun to take advantage of the ACCC conductor’s numerous attributes. Its rapid adoption has been based on three factors: Performance, Reliability and Cost.

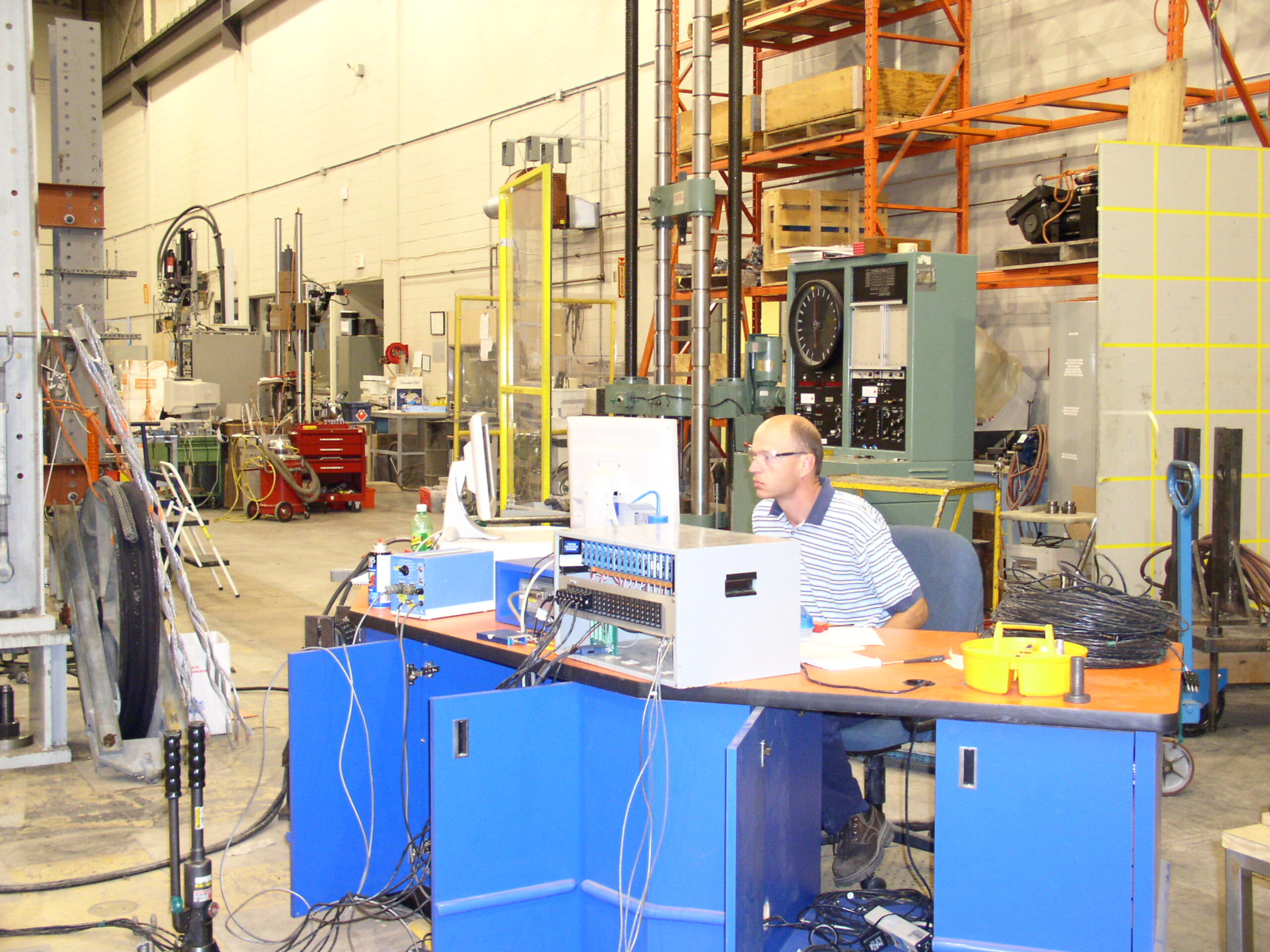

While the ACCC conductor’s performance was easy to confirm, literally hundreds of tests established its reliability and longevity characteristics. The data compiled has been extensively reviewed by numerous utilities, and some, such as State Grid China, National Grid UK, and American Electric Power, have even developed and performed their own tests. Nevertheless, for utility reconductor projects, new lines, long spans and many other applications, the ACCC conductor has been selected not only for its performance and longevity advantages, but because it offered the best economic solution available.

One example of a high value application replaces a conventional conductor circuit with the same diameter ACCC conductor using the same towers. The reconductored circuit can now carry twice the current of the replaced conventional conductor and with 30% lower line losses. The saved energy and reduced carbon emissions provide a rapid economic payback for the project and the increased capacity enables more renewable generation to be brought into the generation mix. All good outcomes.