During the last week of May, Southern California Edison (SCE) energized their first ACCC conductor installation in Palm Springs, California, an area known for its very hot summers and strong winds. The project was undertaken to replace aged ACSR conductor that was exhibiting excessive thermal sag.

The SCE reconductoring project not only mitigated sag issues – while enabling load growth – the project was also completed quickly and economically with virtually no environmental impact, as the ACCC conductor enabled the use of the existing structures with no modification or need for structural replacement.

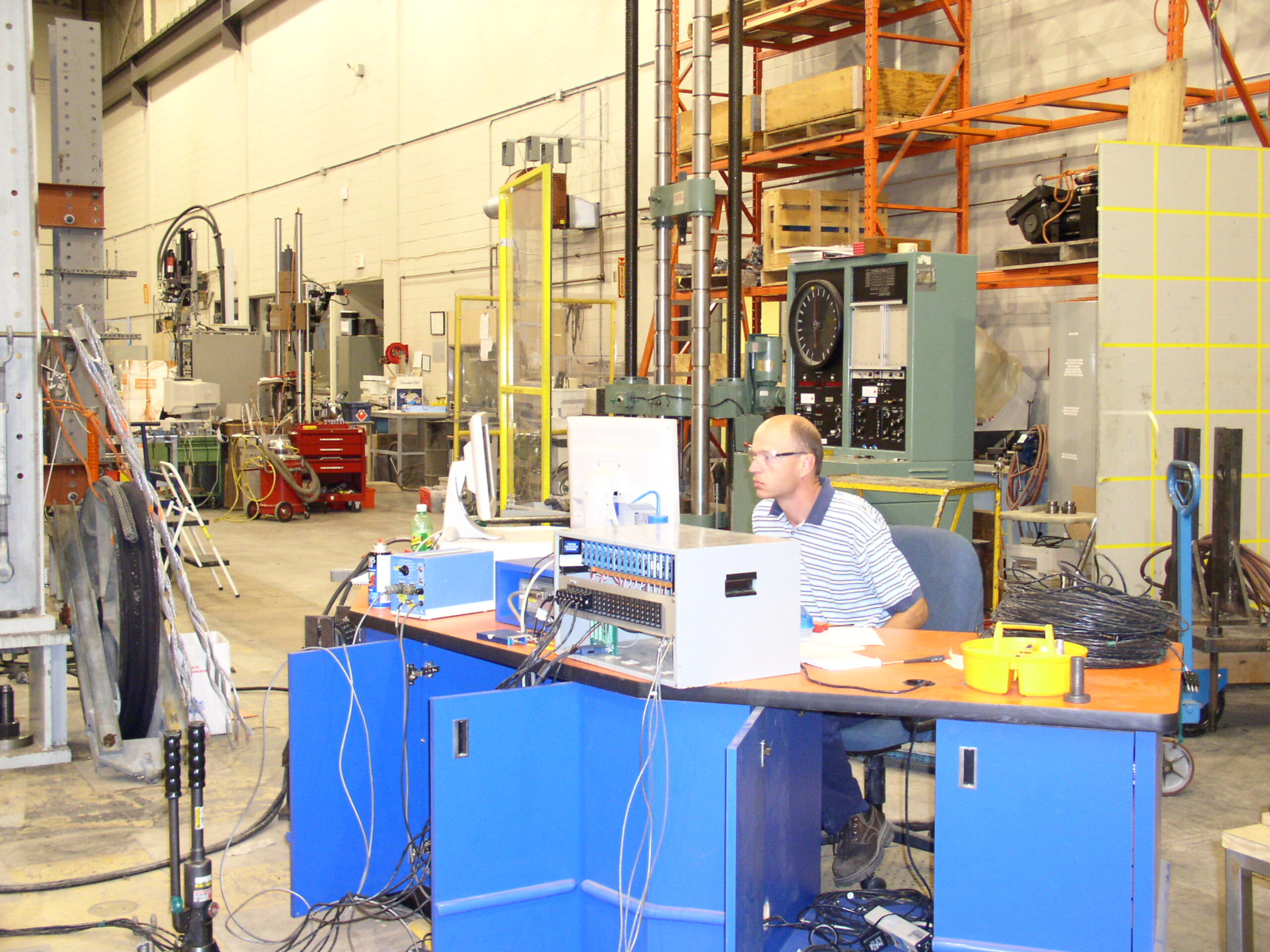

The 115 kV reconductor project used approximately 38 kilometers of 530 kcmil (268.4 mm^2) Laredo size ACCC conductor manufactured by General Cable to meet compliance requirements of the existing line connecting the Eisenhower and Thornhill substations near the Palm Springs Airport. Hardware for the project was supplied by Burndy and the SCE crew used Sherman Reilly equipment during the installation.

CTC Global’s master installer David Pearce provided training to 13 SCE crew members and remained on site to help as needed. Even though the area is well developed, care was still taken to avoid harming any of the “local residents” that include the Coachella Valley fringe-toed and flat tailed ‘horned’ lizards, and the Palm Springs round-tailed ground squirrels. The project was completed under a maintenance permit and went very smoothly with SCE’s outstanding crew.

This installation marks the first of many scheduled and State approved ACCC conductor upgrades over the next several months. CTC Global is pleased that SCE recognizes the benefits the ACCC conductor offers and are very happy that SCE continues to add certified / trained crew members to their team, as they are also nearing completion of their second ACCC installation north of Los Angeles.

SCE’s upgraded line offers greater capacity, improved reliability and fire safety due to its high strength and low sag composite core. The ACCC conductor’s increased aluminum content (without a weight or diameter penalty) also serves to reduce electrical line losses by an estimated 30 percent. Reduced line losses not only reduces fuel consumption and associated emissions, it also frees-up generation capacity that is otherwise wasted. CTC Global applauds SCE’s commitment to building a more robust, resilient and efficient power grid in Southern California.