The vast majority of our Nation’s high voltage electric power grid (above 11 kV) was built several decades ago using aluminum conductors reinforced with steel cores. These are known as “ACSR” conductors and were introduced in the early 1900’s. In the 1970’s a higher temperature version of ACSR was introduced that used fully annealed (pre heated) aluminum that could increase line capacity by operating at higher temperatures. These were known as “ACSS” conductors.

In 2003, a major blackout in the Northeast United States and parts of Canada occurred during a heatwave due to poor communications between grid operators, mis-calibrated telemetry devices, computer reboot failures, and excessive conductor sag that led to cascading sag-trip outages.

In 2005, a new carbon fiber core conductor was commercialized. This product was known as ACCC® Conductor. It offered greater strength, improved resistance to corrosion and fatigue, and is capable of carrying twice the current of conventional ACSR conductors with substantially reduced electrical power losses compared to ACSR or ACSS conductors of the same diameter and weight. The composite core also does not stretch when it heats up – which prevents dangerous conductor sag that can trigger power outages and cause wildfires.

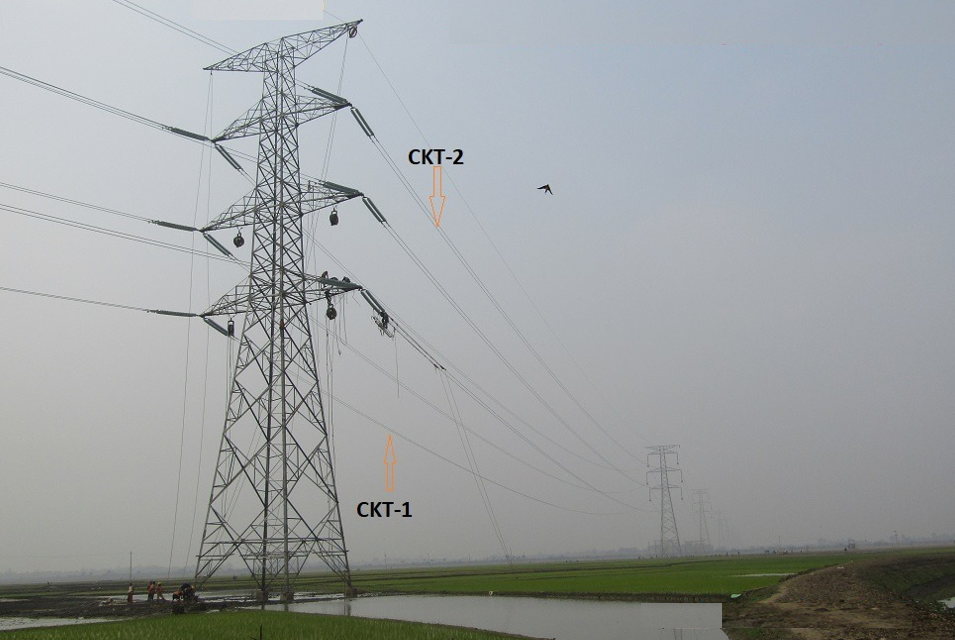

While a number of other composite core conductors have been introduced over the last two decades, the ACCC® Conductor has been deployed to more than 1,325 projects in 67 countries. While a number of utilities and project financiers specify ACCC® Conductor for new transmission and sub transmission line lines, they are typically chosen to replace conventional ASCR / ACSS conductors to increase line capacity and improve reliability and resilience on existing lines using existing structures. This “Advanced Reconductoring” is a very quick and cost-effective way to deliver more power and ‘build-in’ redundancy for planned or unplanned outages – and essentially future proof the grid. Larger projects are often completed in phases with immediate favorable results.

While several major utilities in the United States have deployed ACCC® Conductors to carry more current and mitigate sag infractions, many other utilities are also using ACCC® Conductor to reduce electrical power losses to ‘squeak more power’ out of existing (or new) generation assets. Reduced electric power losses can not only free-up generation assets otherwise wasted, it can also reduce fuel consumption and associated GHG emissions. Many entities worldwide are using ACCC® Conductor to help them reach their sustainability goals at a very low cost while also helping reduce the cost of delivered power to their customers.

For more information, contact [email protected]