The need for new and existing transmission lines to carry higher levels of current became apparent in the 1970’s and has grown exponentially since then. The electrification of transportation, homes, business, new data centers (etc.), coupled with the need to link more renewable generation resources to meet sustainability goals has raised the urgency of this task to a very high level.

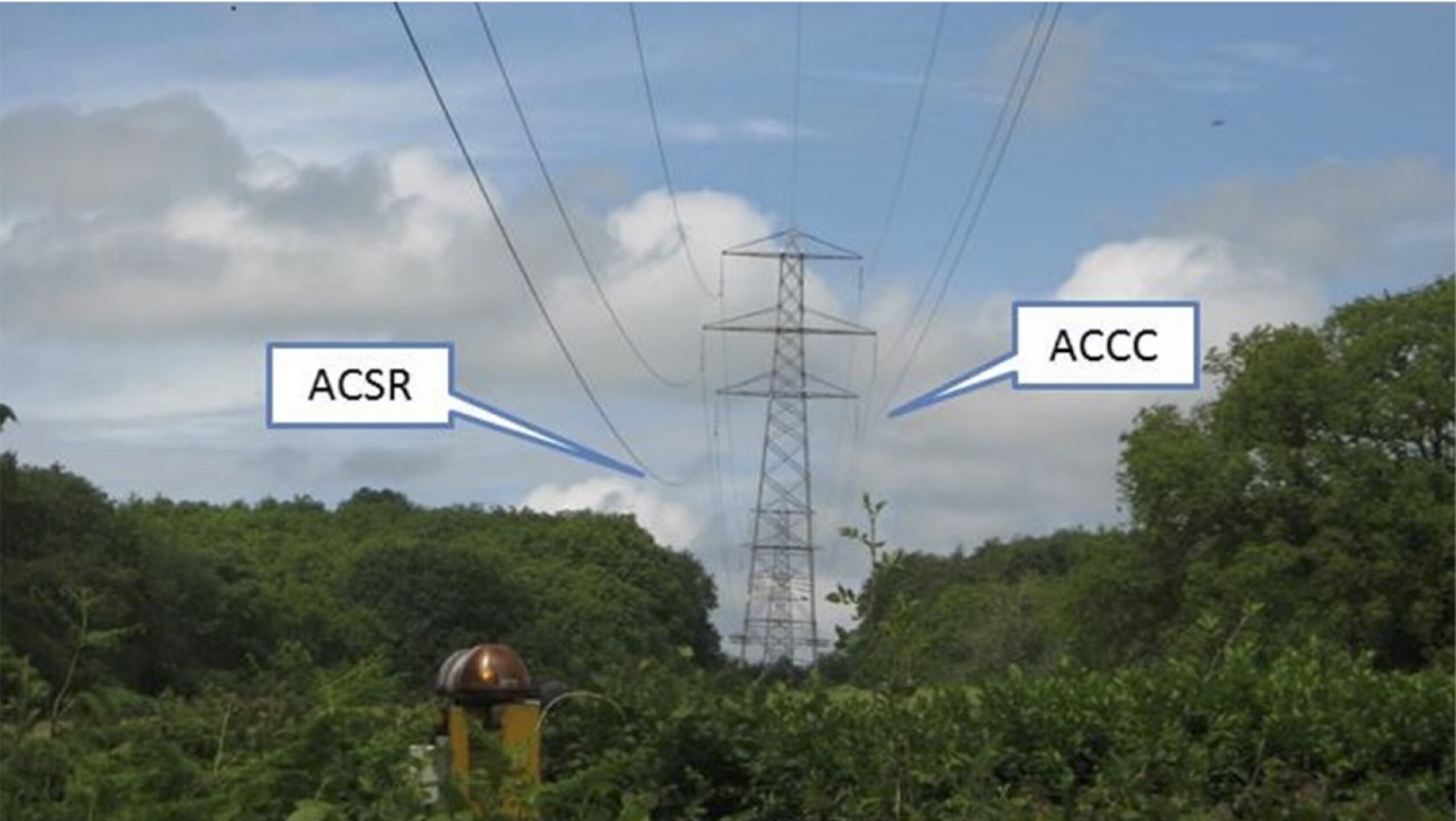

In the 1970’s, conductor manufacturers introduced the ACSS conductor which was designed to operate at higher temperatures compared to legacy steel core ACSR conductor introduced in the early 1900’s. The only difference between ACSR and ACSS conductor was that the ACSS conductor used fully annealed aluminum that allowed higher operating temperatures associated with increased amperage. The use of fully annealed aluminum reduced the strength of ACSS by ~25%. Years later, several manufacturers utilized higher strength steel cores to regain overall strength. This, however, offered very little value as the coefficient of thermal expansion – which dictates a conductor’s sag under higher electrical loads – remained the same.

While it is possible to use larger, heavier, more expensive conductors to increase line capacity, their added weight (also a contributor to conductor sag) requires the use of taller, stronger, more expensive structures generally placed on more substantial foundations. While overall project costs on new transmission lines will go up significantly as a result, replacing structures on existing transmission lines creates substantial permitting challenges, requires long-term power outages, and results in less than favorable environmental impact.

Advanced Conductors, that use carbon fiber composite cores, offer a highly cost-effective alternative for building new transmission lines as well as ‘reconductoring’ existing transmission lines.

When used on new lines, the ACCC® Conductor, for example, enables greater spans between fewer and/or shorter less expensive structures to reduce overall project costs and construction timeframes. While ACCC® Conductors offer ~twice the capacity of ACSR conductors and slightly more capacity than ACSS conductors (of equivalent weight and diameter), the ACCC® Conductor’s improved efficiency reduces transmission line losses by 25 to 40% or more. Improved efficiency not only reduces fuel consumption and associated GHG / CO2 emissions, it also frees up generation capacity otherwise wasted. The ACCC® Conductor’s composite core is also impervious to corrosion and cyclic load fatigue. These attributes result in improved grid reliability and resilience and deliver tens of millions of dollars of direct benefits to utilities, ratepayers, and the environment over the conductor’s anticipated service life of 40-50+ years.

In February 2024, the Energy Institute at Haas – UC Berkeley in association with GridLab, published “Accelerating transmission expansion by using advanced conductors in existing right-of-way.” This paper and other similar papers published over the last five years, explain how large-scale reconductoring with advanced composite-core conductors can cost-effectively double transmission capacity within existing right-of-ways (ROWs), quickly and with very few permitting challenges and environmental impact. Their paper concludes that “this strategy unlocks a high availability of increasingly economically viable renewable generation resources in close proximity to the existing network.” The Haas implementation of reconductoring with Advanced Conductors in a model of the United States power system showed that reconductoring can help meet over 80% of the new interzonal transmission needed to reach over 90% clean electricity by 2035 given restrictions on greenfield transmission build-out. “With $180 billion in system cost savings by 2050, reconductoring presents a cost-effective and time-efficient, yet underutilized, opportunity to accelerate global transmission expansion.”

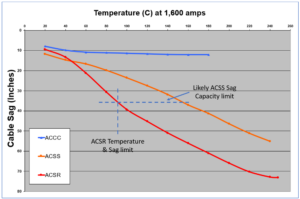

The Haas report made it very clear that ACSS conductors would not be suitable for various reasons including the ACSS conductor’s propensity to sag. The graph below (which used data acquired from Hydro One testing at Kinectrics Lab) shows the differences in sag and temperature of ACSR, ACSS, and ACCC® Conductors of the same diameter and weight. Assuming that existing structures were designed to support this “Drake” size conductor and that the ACSR conductor would exceed allowable sag limits at ~90° C (see dashed lines), it becomes apparent that the ACSS conductor would exceed sag limits far before accommodating much additional capacity. Note that the temperature of the ACCC® Conductor is much cooler than the ACSR and ACSS conductors under a test load of 1,600 amps for all three conductors. The cooler temperature reflects greatly improved efficiency and substantially reduced line losses.

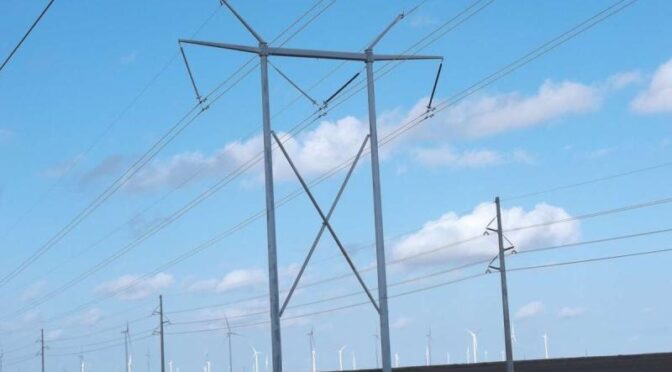

In 2016, after considering the ACSS conductor, AEP completed a well-known ACCC® Reconductoring project on two parallel 120 circuit mile 345 kV in Texas. In addition to doubling the capacity of the lines – without the need to replace existing structures – the use of ACCC® Conductor also reduced line losses by 300,000 MWh/year. Based on all combined sources of generation at that time, the project also reduced CO2 emissions by 200,000 metric tons (the equivalent of removing 42,000 cars from the road). This project, performed while energized (without any substantial outages), and also freed up 34 MW of otherwise wasted generation capacity. The use of ACCC® Conductor vs ACSS saved AEP tens of millions of dollars and months of time and will deliver reliable and measurable benefits for decades.

Key Take Aways:

· Evolution in Conductor Technology: ACSS conductor was introduced as an improvement over legacy ACSR conductor to handle higher temperatures and currents. However, its reliance on aluminum with reduced strength and conventional steel cores limited its effectiveness.

· Limited Improvement with Steel Cores: Attempts to improve ACSS conductor by using higher-strength steel cores offered marginal benefits as it didn’t address the fundamental issue of sag under higher electrical loads.

· Challenges with Traditional Solutions: While increasing conductor size can enhance line capacity, it necessitates larger, heavier, and costlier structures, leading to significant project cost escalation and environmental impacts.

· Benefits of Advanced Conductors: ACCC® Conductors, featuring carbon fiber composite cores, present a more cost-effective solution for both new transmission lines and reconductoring existing ones. They enable greater spans between structures, reducing project costs and construction timeframes.

· Performance Superiority: ACCC® Conductors offer approximately twice the capacity of ACSR conductors and slightly more than ACSS conductors of equivalent weight and diameter. Additionally, they significantly reduce transmission line losses by 25 to 40% or more, enhancing efficiency and grid reliability.

· Long-Term Benefits: The composite core of ACCC® Conductors is impervious to corrosion and cyclic load fatigue, ensuring improved grid reliability and resilience over their anticipated service life of 40-50+ years.

· Environmental Impact: ACCC® Conductors contribute to reducing fuel consumption, greenhouse gas emissions, and wasted generation capacity, offering direct benefits to utilities, ratepayers, and the environment.

· Research Support: Academic studies, such as the one by the Energy Institute at Haas – UC Berkeley, endorse the effectiveness of reconductoring with advanced composite-core conductors to double transmission capacity within existing right-of-ways, with minimal permitting challenges and environmental impact.

· Real-World Implementation: Successful projects like the ACCC® Reconductorization by AEP in Texas demonstrate the tangible benefits of using advanced conductors, including doubling capacity, reducing line losses, cutting CO2 emissions, and saving costs and time.

Overall, the comparison underscores the superiority of ACCC® Conductors over traditional solutions like ACSS, highlighting their technical advantages, cost-effectiveness, and environmental sustainability.

Additional Resources / References:

–CurrENT Europe: Recommendations for the Deployment of DSO Projects

–WRI: “Getting the Most out of Existing and New Advanced Transmission Technologies”

–DOE: Failing to invest in grid-enhancing tech will be a ‘massive miss.’

–CTC Global: Engineering Transmission Lines with High-Capacity Low-Sag ACCC® Conductor