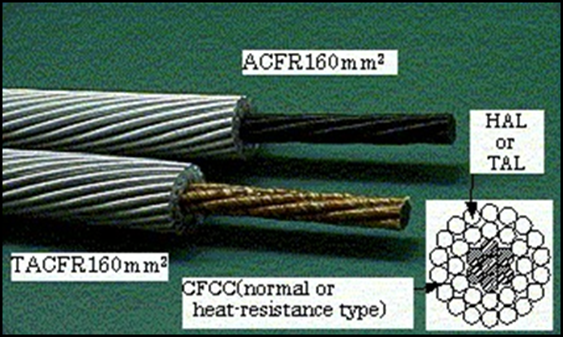

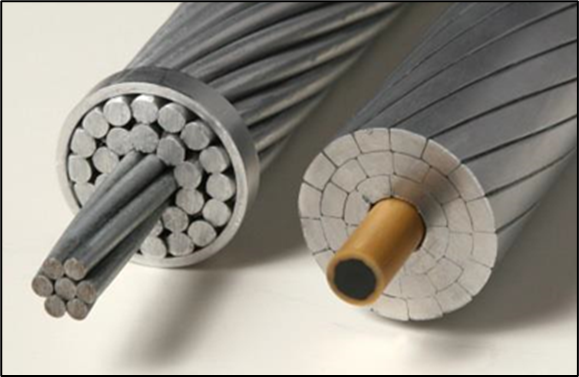

In 2002, 3M introduced a multi-strand core using ceramic fibers rather than carbon fibers. The conductor design used an aluminum matrix rather than a thermoplastic or thermoset matrix. Because the core strands are not as strong as steel, 3M also chose a higher strength and temperature-resistant aluminum alloy that contains zirconium to match the overall strength of a comparable ACSR conductor. Though the core is not as strong as steel, it does offer a lower coefficient of thermal expansion at a much lower weight compared to steel. While it does offer higher capacity and lower sag, its ceramic-reinforced core strands are extremely brittle and can be easily damaged during installation or as a result of the transverse impact. It is estimated that approximately 200 ACCR projects have been completed globally.

During the same time period in the U.S., W. Brant Goldsworthy began working on an alternative carbon fiber composite core conductor known as CRAC (Carbon Reinforced Aluminum Conductor). Goldsworthy’s work was initially sponsored by the California Energy Commission and Southern California Edison. The initial product was designed to incorporate a central strand containing a fiber optic cable surrounded by six trapezoidal-shaped pultruded carbon fiber strands.

In 2003, CTC Global, through a business agreement with Goldsworthy, began the development of a carbon and glass fiber composite core product, leading to the development of what today is known as the Aluminum Conductor Composite Core ACCC® Conductor. During the prototype phases of ACCC® product development, CTC considered many alternative approaches to building a composite core conductor including several multi-strand approaches. After the development of many prototypes and substantial testing, CTC determined that a single-core approach was best able to maximize the physical and mechanical properties of the conductor while mitigating dead-end and splice connection concerns.

The single-strand approach and manufacturing process enabled the incorporation of a very robust glass fiber barrier layer into the unified structure. This layer provides galvanic isolation between the carbon fiber and aluminum, improved flexibility and toughness, while providing protection to the central carbon fibers. The central core in the Drake size ACCC® Conductor utilizes more than 675,000 individual carbon fibers and more than 400,000 glass fibers. The thermoset epoxy matrix serves to help the fibers share applied loads.

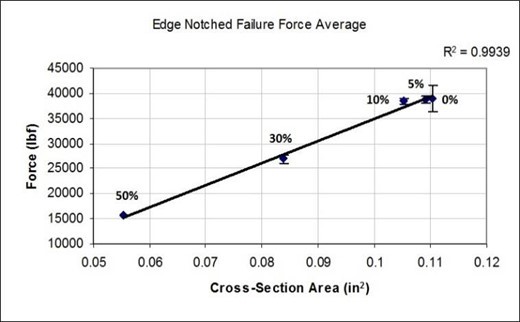

While a multi-strand design in theory may contain damage to the impacted strands, the unified ACCC® Core’s hundreds of thousands of individual strands can still work together in spite of some degree of damage. When damage occurs to a percentage of the individual strands, the resin matrix allows load transfer to the remaining (undamaged) strands. The chart below depicts the linear retention of strength after a 5, 10, 30 and 50 percent loss of material using an ‘edge notch’ test protocol. It is noteworthy that the tensile strength of the standard ACCC® Core is 320 ksi compared to high-strength steel. The ULS version of the ACCC® Core is 375 ksi, much higher than 285 ksi high-strength steel. The ACCR metal matrix core by comparison is 200 ksi (per ASTM Standard B976-11).

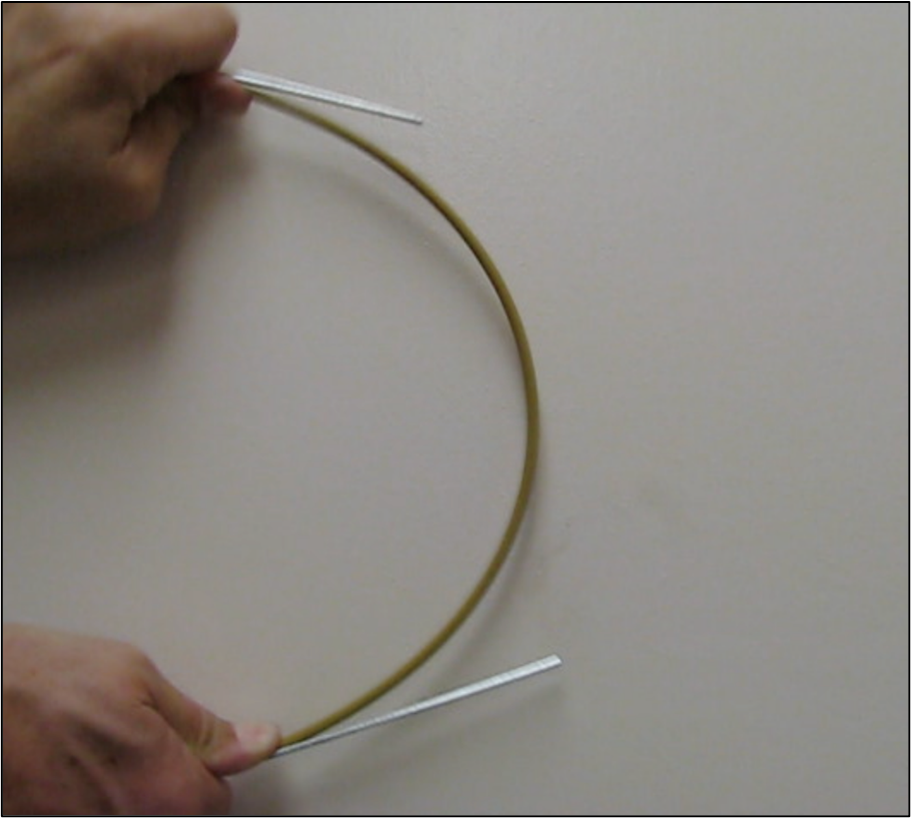

It has been suggested that multiple smaller-diameter core strands offer improved flexibility compared to the larger-diameter unified core. This is not the case as shown in the figure below and video link

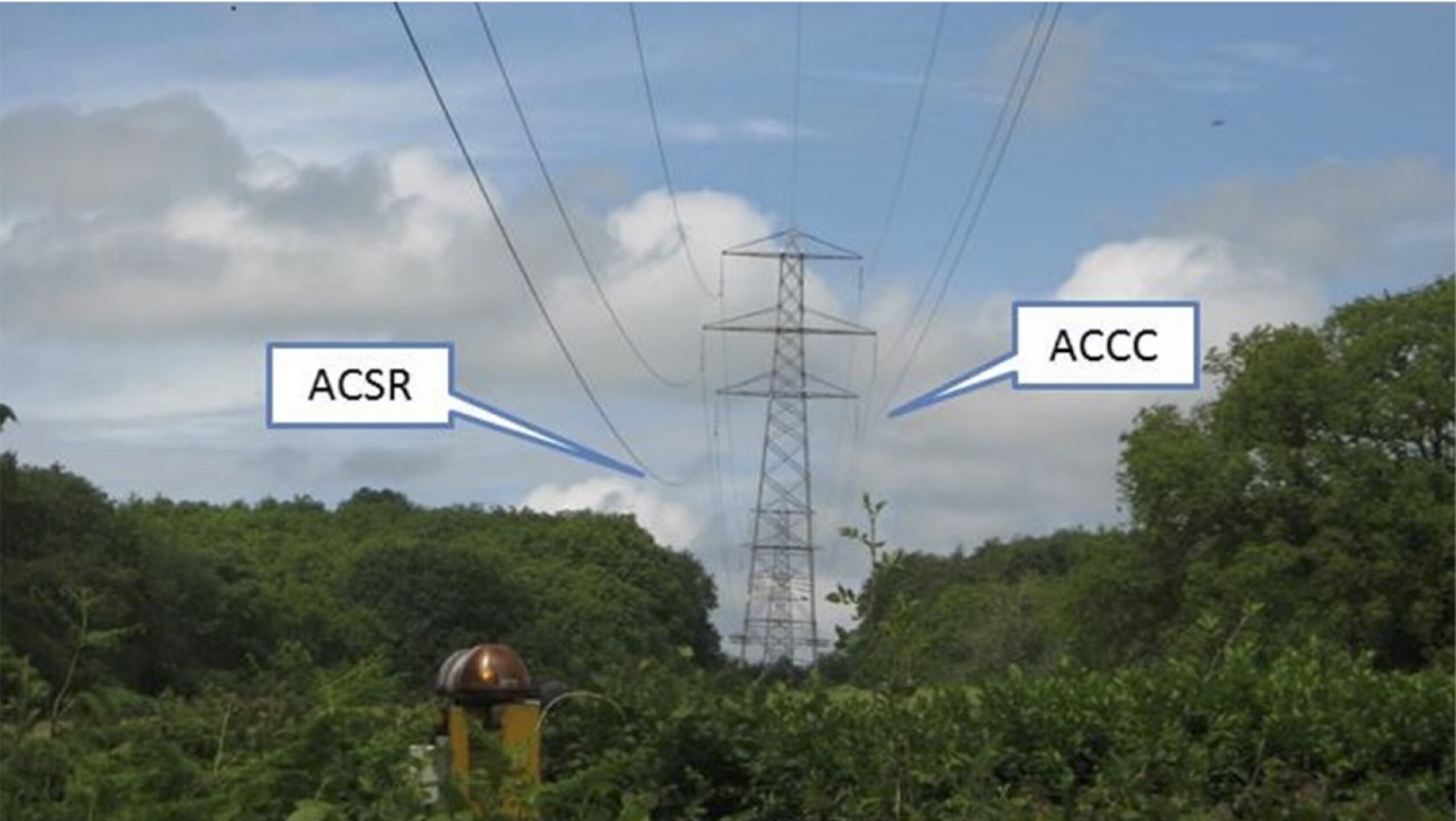

While the multi-piece ACFR and CRAC conductors have not received significant market acceptance (and the ACCR conductor limited acceptance due to very high costs), more than 175,000 km of ACCC® Conductor has been installed at over 1,250 project sites since ACCC was first deployed in 2004. This work includes the successful utilization of ACCC® by over 50 utilities in the U.S. and more than 300 utilities worldwide. Remarkable ACCC® Conductor installations include AEP’s award-winning 240-circuit mile energized 345 kV ACCC Reconductoring project; Trenergy’s 50 km new generation tie lie; and Bouygues Construction’s one-mile river crossing in Mozambique.

The efforts made by CTC Global to help the industry recognize the numerous advantages of carbon fiber-reinforced conductor cores have inspired other manufacturers to develop their own versions. In 2008, Nexans introduced a carbon fiber core conductor known as Lo-Sag™. Like the CTC product, the Nexans product utilizes a single-strand core, but instead of a fiberglass protective layer, Nexans used a thermoplastic coating to prevent galvanic activity between the carbon core and the aluminum strands. Thus far, only a handful of installations of Lo-Sag™ have been completed to date. LS Cable in Korea, DeAngeli in Italy, and TS Conductor in the U.S. also introduced all carbon cores encapsulated in aluminum. DeAngeli offers a multistrand version as well.

In 2015, Southwire introduced “C7™” which is a bare overhead conductor that utilizes a multistrand carbon fiber approach similar to the ACFR design developed in Japan. The seven round core strands utilized in the C7 conductor consist of carbon fibers embedded in a thermoplastic resin matrix. The individual carbon strands are protected from galvanic activity with the aluminum strands by incorporating a PEEK thermoplastic coating similar to the Nexans approach. While the flexibility of the C7’s smaller core strands is improved compared to larger diameter single-strand cores, the smaller all-carbon core strands are more brittle than the carbon-glass hybrid used in the ACCC® Conductor and are more susceptible to damage.

While the C7 product divides the thousands of individual carbon fiber strands into 7 subdivisions, the air gap between the individual strands reduces the initial strand count by approximately 25% compared to a single-strand design. The multi-strand approach also exhibits a much higher surface to core area ratio. When considering the severity of the environment in which overhead conductors perform, higher overall surface area ratios represent potentially greater exposure to chemical, thermal and mechanical aging mechanisms. In addition to the increased surface area, the protective PEEK thermoplastic coating used in the C7 design may degrade over time due to abrasion. This could lead to a galvanic response between the carbon fiber and aluminum strands (in the presence of moisture) which could cause accelerated corrosion of the aluminum.

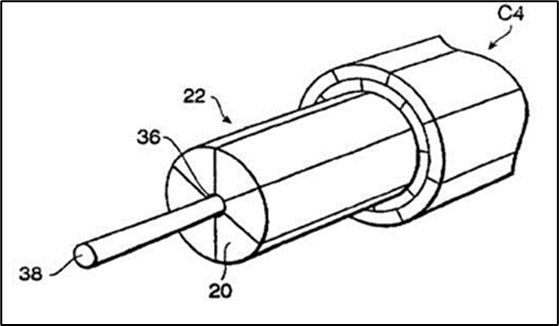

Though CTC considered the potential benefits of multi-strand designs – even though manufacturing costs were presumed to be higher – CTC also considered the challenges associated with dead-ending and splicing a multi (particularly round) strand design.

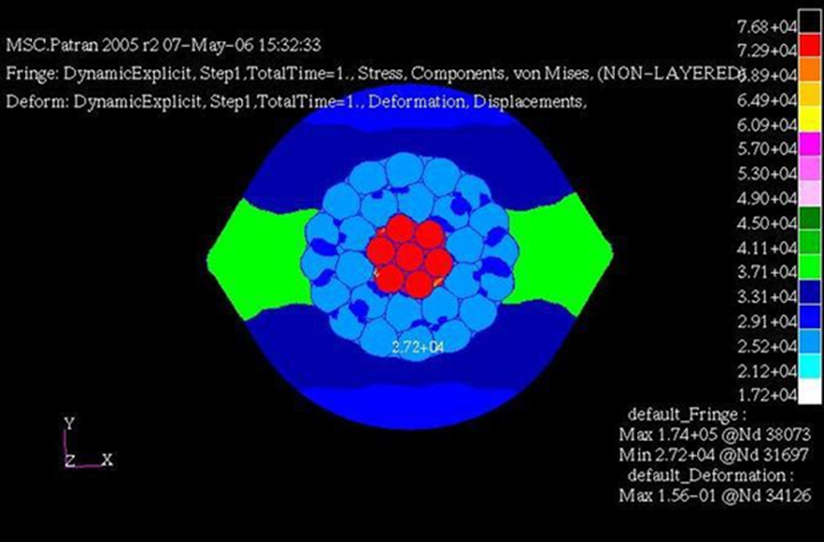

When compressive forces are exerted on round strands, the stress at the interface between the round wires is substantial because of the very small points of contact between each of them. During the compression fitting of dead-end and splice hardware conventional metal strands will plastically deform and yield. Thermoplastic and thermoset composites, in the short term, do not plastically deform.

Because of this, the risk of fracturing under high non-uniform compressive loads (commonly used to install dead-ends and splices) may be relatively high.

Over longer periods of time, thermoplastic materials will, however, plastically deform and creep, especially in the transverse direction where there is no fiber contribution to compressive stress. Thus, in addition to the initial risk of fracture, over extended periods of time creep may reduce the compressive forces required to effectively retain multiple core strands.

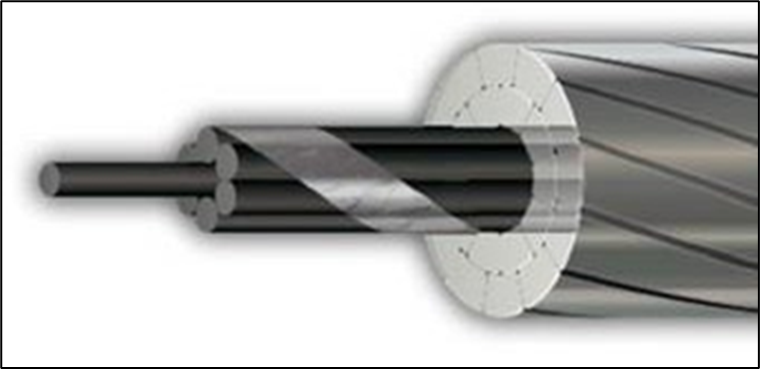

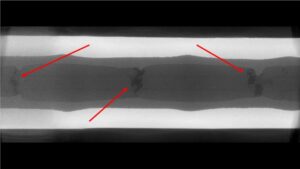

Another issue with aluminum-lined compression devices used for carbon fiber cores is the axial stress created during compression, which can cause the aluminum to expand outward and exceed the strain limits of the cores. This can actually snap the core strands inside the devices. This concern is real and has been seen in devices removed from service after a very short time. This can happen with single or multistrand designs (shown below).

Compressive stress caused axial strain that snapped multistrand carbon core strands

To mitigate these concerns with the single-strand ACCC® Conductor design, CTC developed a collet grip method that enables the assembly to exert a uniform force on the core even as levels of tension increase. The possibility of transverse creep is eliminated by the single core design of ACCC® Conductor because there are no areas of free volume for the thermoset resin to flow. The ACCC® Conductor collet assembly also allows the fully elastic core to stretch as it enters the device without stress concentration to ensure long-term durability. To date, more than one million of these devices have been successfully installed without a single reported failure.

While appropriate handling and the use of correct installation procedures can prevent damage to any conductor type, the flexibility and toughness of the ACCC® Conductor’s composite core is well proven. In addition to a substantial battery of lab tests, a number of field events that include lightning strikes, severe wind and ice loads, fallen tree impact, wildfire, and flying debris have demonstrated the product’s durability.

The impressive performance of the ACCC® Conductor comes as no surprise when the considerable strength and fatigue capability of carbon fibers are considered. The primary difference between steel and carbon fiber behavior lies in how the two materials respond to weak points in their structures. Steel is susceptible, particularly in fatigue, to small flaws or weak points that – when stressed – will grow and eventually fail. Carbon fiber composites have exceptional fatigue resistance and are very insensitive to small flaws in the structure. In the case of the ACCC® Conductor, the core’s robust outer glass fiber layer adds substantial protection to the inner carbon fiber core.

As with any conductor type, the ACCC® Conductor is not completely immune from damage, however, the use of proper installation procedures can ensure decades of reliable high performance. While a few installation-related events damaged the composite core, much has been learned at over 1,250 ACCC® Installations in 66 countries in every type of environment and terrain. This experience has helped CTC Global’s team of Master Installers teach others how to avoid making the same easily avoidable mistakes. In 2020, fiberoptics were added to the ACCC® Core. CTC Global’s ACCC InfoCore® System now allows linemen to check and document core integrity when mishandling or damage is suspected.

The ACCC® Conductor is manufactured to ASTM Standard B987/B987M-20 “Standard Specification for Carbon Fiber Composite Core (CFCC/TS) for use in Overhead Electrical Conductors.” The ACCC® Conductor is patented internationally. The core is produced at CTC Global’s ISO 9001-2015 certified manufacturing facilities in the U.S., Indonesia, Paraguay, and China and will soon be produced in Pune, India, in mid-2024. Every reel of ACCC® Core is inspected and tested. The reels of core are carefully packaged and shipped to one of more than 35 certified and authorized manufacturing partners globally.