Introduction: The ACCC® Conductor has been selected for over 1,250 projects in the U.S. and other countries because it provided the best economic and technical solution to many T&D challenges. It is slightly more expensive on a per foot/meter basis, nevertheless, as the dominant and most proven Advanced Conductor on the market today, its numerous advantages deliver far more value and overall project and lifecycle cost savings than legacy conductors. There are a number of reasons for this and plenty of examples to study.

Overview: As demand for affordable and reliable energy continues to grow in tandem with efforts to combat climate change by deploying and connecting more renewable generation resources, reconductoring with Advanced Conductors has been found to be an excellent solution for more than 250 major utilities worldwide. In the United States, this includes American Electric Power, NV Energy, PacifiCorp, ComEd, Southern California Edison and 40+ others.

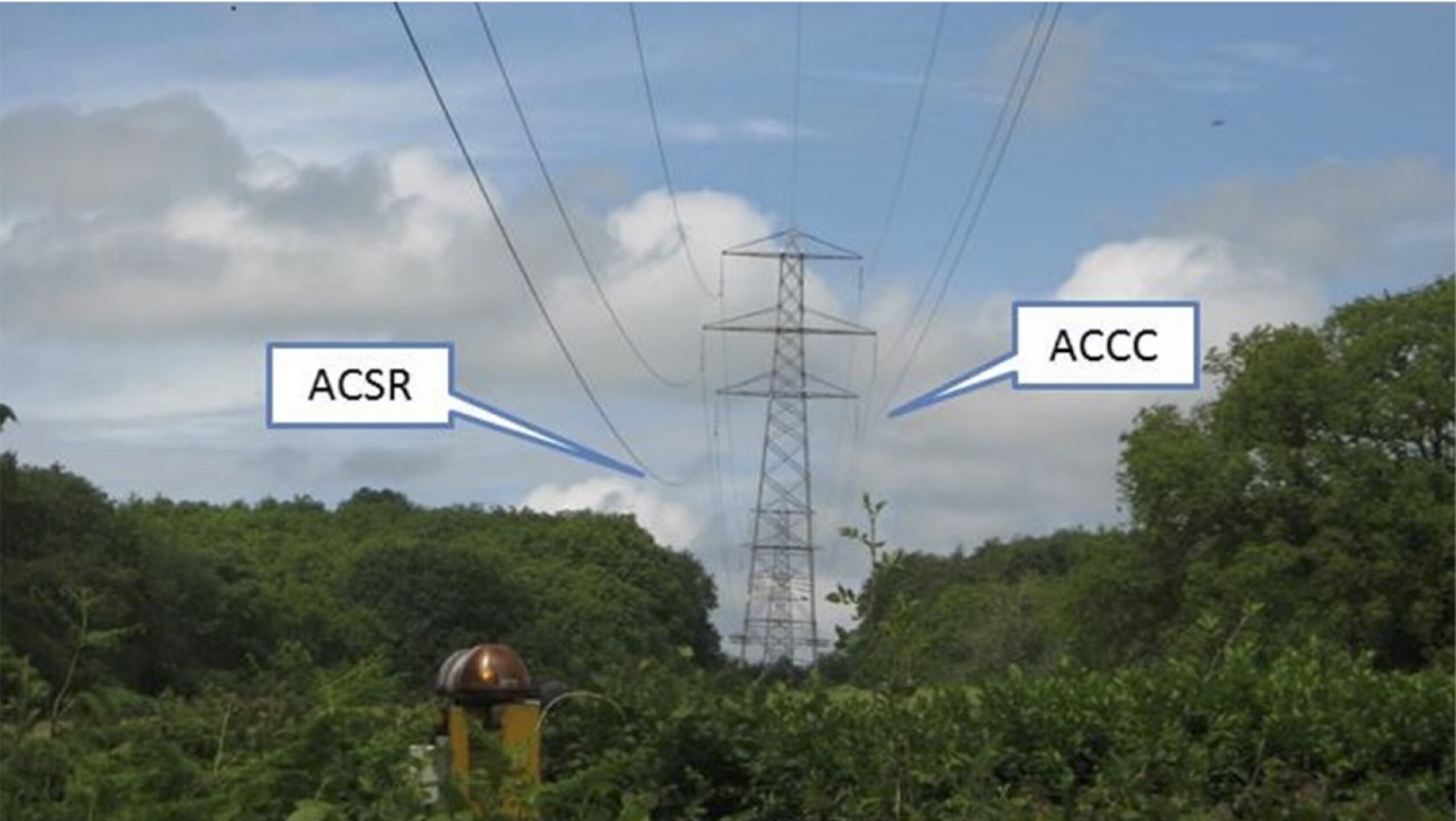

Background: In the past, increasing the capacity of an existing transmission line generally required removing and replacing existing structures with larger/taller structures on stronger foundations to support larger/heavier conductors. In the 1970’s the ACSS conductor was introduced as a higher temperature version of the standard steel reinforced aluminum ACSR conductor. The difference being that the ACSS conductor came pre-annealed from the factory so it could carry higher current at higher operating temperatures. While pre-annealing offered slightly lower electrical resistance, the thermal sag characteristics of ACSS were very similar to ACSR conductors, so, while the ACSS conductors could carry more current, they are heavy and exhibited more sag which limited their overall capacity benefits unless structures were raised or replaced. Despite these limitations, the ACSS conductor was categorized as a High-Temperature, Low-Sag (“HTLS”) conductor and the advent of reconductoring began.

Benefits: The attributes of Advanced Conductors are ideally suited for reconductoring projects. The ability to double the capacity of the existing grid by swapping out aged conductors with high capacity, energy efficient ACCC® Conductor has been found by researchers and U.S. Utilities to be one of the fastest and lowest costs means of helping reach electrification and sustainability goals and link and deliver new renewable sources of generation. Reconductoring can be performed quickly without the need to replace or modify existing structures. These factors substantially minimize permitting challenges, expedite project approvals, reduce construction timeframes, free-up personnel and equipment, reduce environmental impact, and reduce project costs and impact on ratepayers.

Example: In 2016, Southern California Edison had capacity constraints on their Big Creek Transmission Corridor that resulted in load shedding. The Big Creek transmission corridor connects Los Angeles with several hydro generation facilities in the foothills of the Sierra Nevada Mountain range about 200 miles north of LA. The line also supports other communities along its path. To mitigate load shedding SCE submitted a proposal the California Independent System Operator (CAISO) and the California Public Utility Commission (CPUC) requesting approval to rebuild their corridor at an estimated cost of well over $80 million dollars. The PUC, who was aware of the ACCC® Conductor, suggested that SCE consider reconductoring with an Advanced Conductor. SCE resubmitted their application with an ACCC® Reconductoring option, and the project was approved, with tens of million in savings. This project supported SCE’s intent, delivered the desired outcome by increasing line capacity from 936 to 1520 peak amps, and saved themselves and ratepayers substantial time and money.

Using the ACCC® Conductor has helped SCE increase the capacity of 27 transmission lines in Southern California, mitigate sag infractions, access cleaner sources of generation and move them several steps closer to meeting their 2045 sustainability goals – all at a very modest cost.

Conclusion: Though Advanced Conductors are more expensive than conventional steel reinforced conductors on a per foot/meter basis, their ability to double the capacity of existing transmission lines can substantially lower the cost of delivered energy to consumers – with several other intrinsic benefits. It is also noteworthy that the added aluminum content of the ACCC® Conductor not only supports higher current flow, it also reduces electrical resistance that converts electrical energy to (wasted) heat. While the ‘costs’ of transmission line losses in the United States are generally passed through to consumers, a 30% reduction in line losses offered by the ACCC® Conductor can reduce fuel consumption, associated GHG / CO2 emissions, and water resources consumed by thermal power plants – all while freeing up wasted generation capacity. The expression “efficiency is the fifth fuel” is not new, but policy makers have already begun introducing legislation where efficiency and other ‘social benefit’ considerations will be reviewed prior to project approval and considered in rate base ROI. The time to abandon 100 year old conductor technology is upon us.