Background:

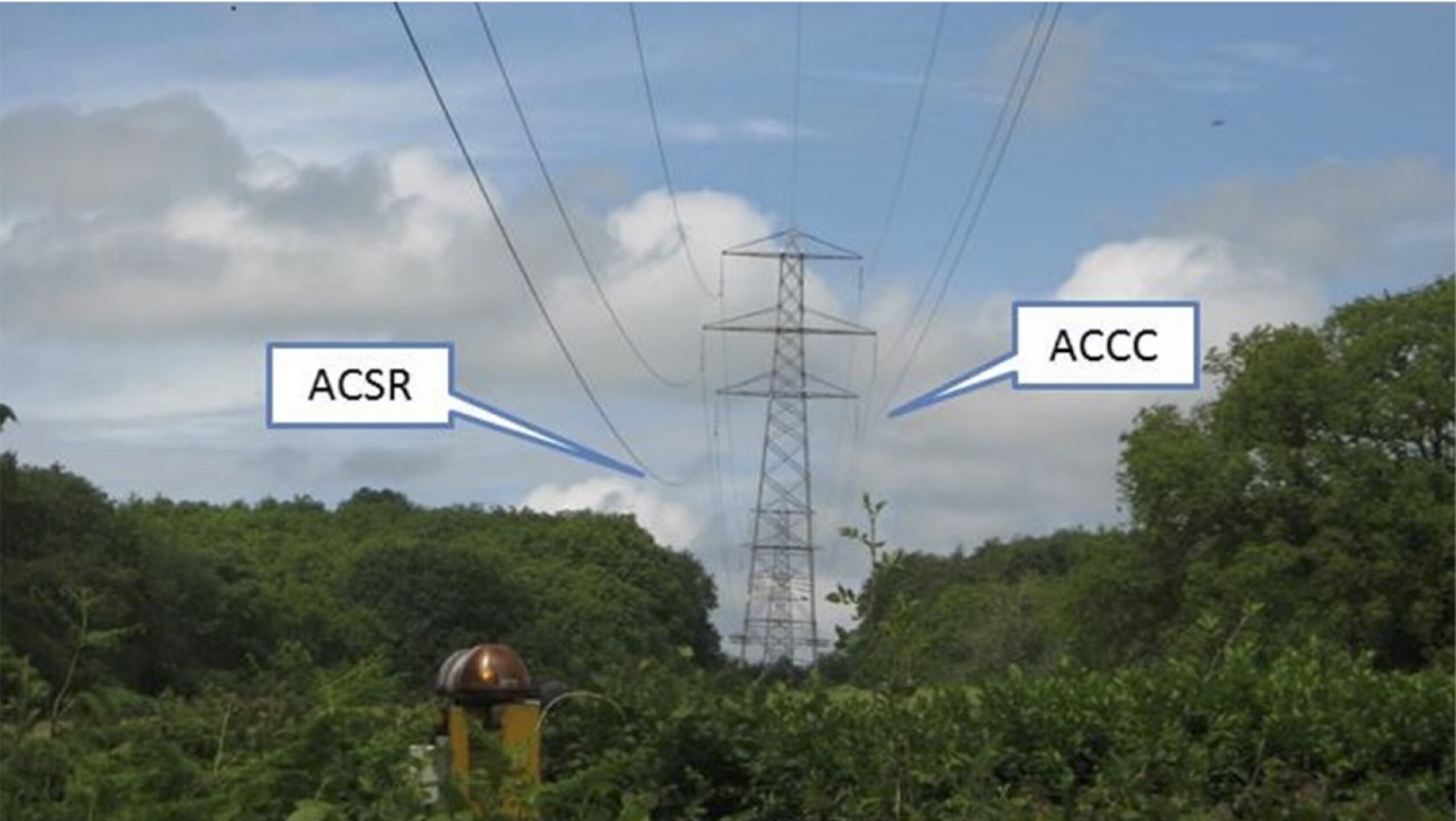

In early 2003, CTC Global (formerly Composite Technology Corporation) introduced the high-capacity, low-sag ACCC® Conductor. The ACCC Conductor essentially established the benchmark for high-performance overhead conductors with nearly 1,100 projects completed in 65 countries. The ACCC Conductor uses a hybrid carbon and glass fiber composite core that offers numerous advantages that serve to improve the efficiency, capacity, reliability and resilience of the world’s electric power grid. CTC Global currently manufactures the ACCC Conductor’s composite core in the U.S., China, South America, and Indonesia to support 35 international conductor manufacturers and over 250 utility and industrial customers.

Over the last several years CTC Global continued to expand its capabilities and advance conductor technology. The introduction of the ACCC ULS (ultra-low sag) and ACCC AZR (aluminum-zirconium reinforced) product launches are two examples. Most recently, CTC Global commercialized the ACCC InfoCore™ System. Development of the InfoCore® System began in 2015 in an effort to help utilities and their installation contractors confirm that the ACCC Conductor was installed correctly and without damage. The ACCC InfoCore® System also establishes a solid platform for further technical developments.

ACCC InfoCore® System Description:

The ACCC InfoCore® System offers linemen the ability to confirm that the integrity of the ACCC Conductor’s composite core was not damaged during shipping, handing or installation. The System uses optical fibers embedded in the ACCC Conductor’s composite core that allow proprietary light signals to verify that the core is free of any damage that could have been caused by impact, excessive bending, equipment failure, or other means. While these occurrences rarely happen, damage to the structural composite core can cause premature conductor failure.

Examples of events that can damage conductors include excessive bending around undersized or misaligned pullies or sheave wheels; poor reel control which may cause binding; equipment impact; grip failure; or other similar events. In addition to the embedded optical fibers, the ACCC InfoCore® System also uses a transmitter, receiver, control pad, and other devices used to prepare the conductor for testing. All required components are contained in a durable light-weight case that can be deployed to any jobsite. Linemen can be trained in minutes and testing can be performed in seconds.

How it Works:

When reels of ACCC® Conductor are delivered to the project site and/or before they are installed, linemen use a conductor circumciser to remove a short length of aluminum strands to expose the composite core. A high-speed cutter and polisher are used to prepare the core for inspection at each end of the reel. A transmitter is attached to one end of the reel and a receiver is attached at the other end. A control pad operator records images from the wireless receiver for review and approval. Data from each test recorded by the control pad can be uploaded to the cloud for archiving and review by others.

While the inspection process can take place prior to installation to ensure that the conductor was delivered in good condition (free of any core damage), it can also be used to inspect the core after the conductor has been pulled in place and fully tensioned before the dead-ends and splices are installed. Efforts are currently underway to commercialize dead-end and splice assemblies that will allow the core to be tested after the connectors are installed which will allow core integrity inspections in the future, and ultimately, in real time.

Validation Testing – Damage Detection:

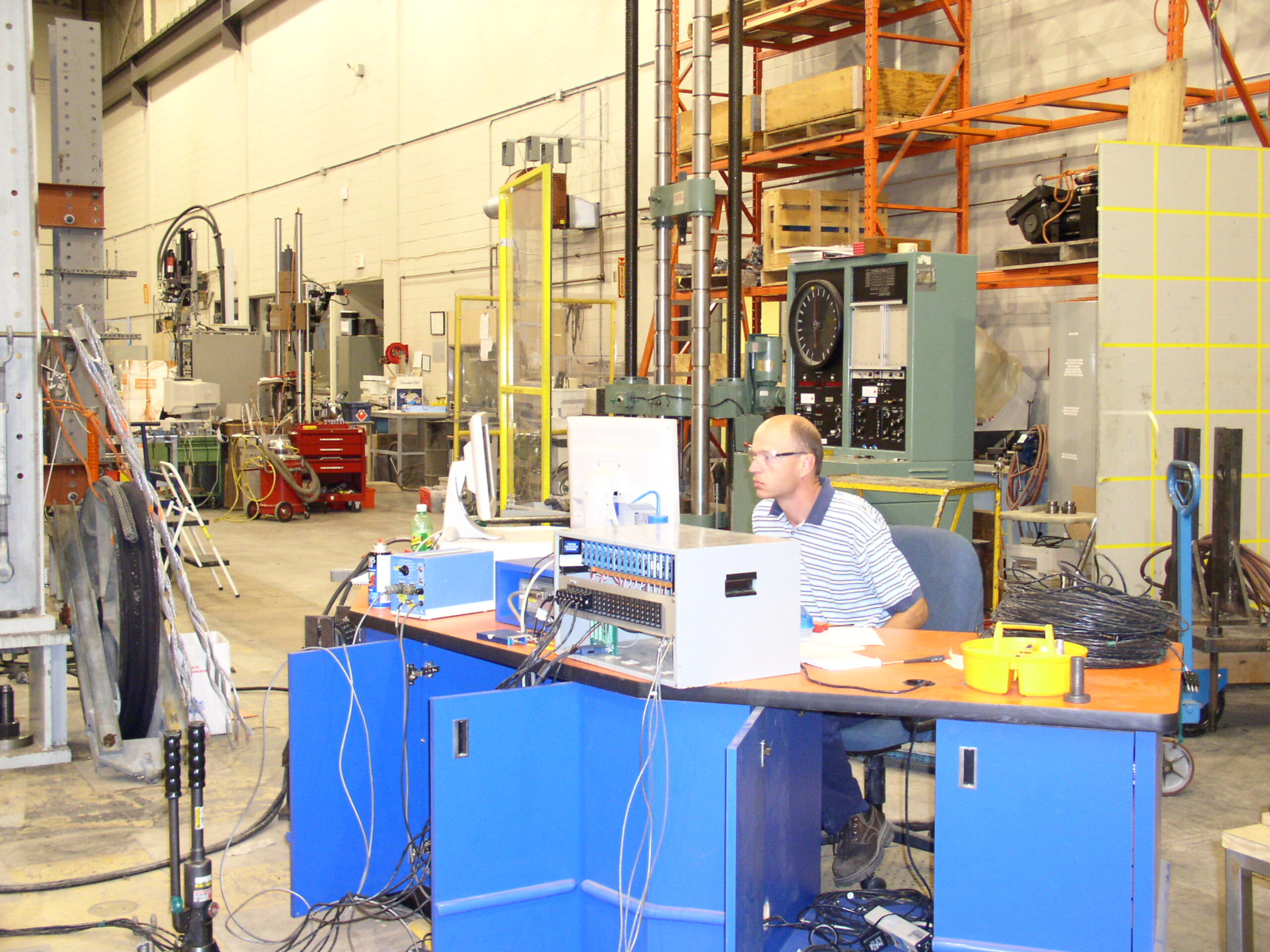

To validate the capability of the InfoCore® System to detect damage, a series of physical and mechanical tests were conducted on a wide range of core sizes. Many of the test protocols were based on a series of design validation tests developed by CTC Global to evaluate new manufacturing processes, materials, and core designs.

While the primary failure mechanism of unidirectional composites is compression buckling caused by excessive bending, the InfoCore® Testing focused on characterizing the ability to detect bending-induced failures. However, all known failure modes were evaluated to verify resistance to false indications of damage and to determine the limits of damage detection.

Testing included: 1) Continuity under tensile load; 2) Continuity during bend over roller sheave; 3) Continuity after tensioned small radius bend test; 4) Continuity after bend on undersize diameter mandrel; 5) Continuity after conductor bend test in Chicago grip; and 6) Torsion testing. These tests were completed in series and witnessed by Element Materials Technology of Los Angeles, California. Element, a certified independent teat lab, and the test series confirmed that the ACCC InfoCore® System performed as designed – without any false indications of damage.

Validation Testing – Property Confirmation:

In addition to damage detection testing, validation testing was also performed on ACCC Core with and without optical fibers to ensure that the performance of the ACCC Core (and Conductor) is identical.

The test results confirmed that all physical, mechanical, chemical, and thermal aging properties of ACCC® InfoCore® are equivalent to standard ACCC® Core without optical fibers. Testing also verified the capability of the optical fiber technique to resist false indications of damage up to the 2% strain limit of the structural carbon fiber and to accurately indicate true indications of damage of any significance.

Summary:

While use of the ACCC InfoCore® System is not mandatory for every project, it does offer utilities and their installation crews the ability to confirm core integrity when installation challenges are anticipated. ACCC® Conductor, ACCC ULS and ACCC AZR characteristics remain unchanged with or without embedded optical fibers; WIR files remain the same, as do installation methods (with the exception of the onsite InfoCore System test protocol). To date, the ACCC InfoCore™ System has been deployed to approximately two dozen projects.

For more information, please visit www.ctcglobal.com or email [email protected]

An overview video is available at https://www.youtube.com/watch?v=R8MTMx-IZy4