Once again, CTC Global has raised the conductor performance bar to improve grid reliability.

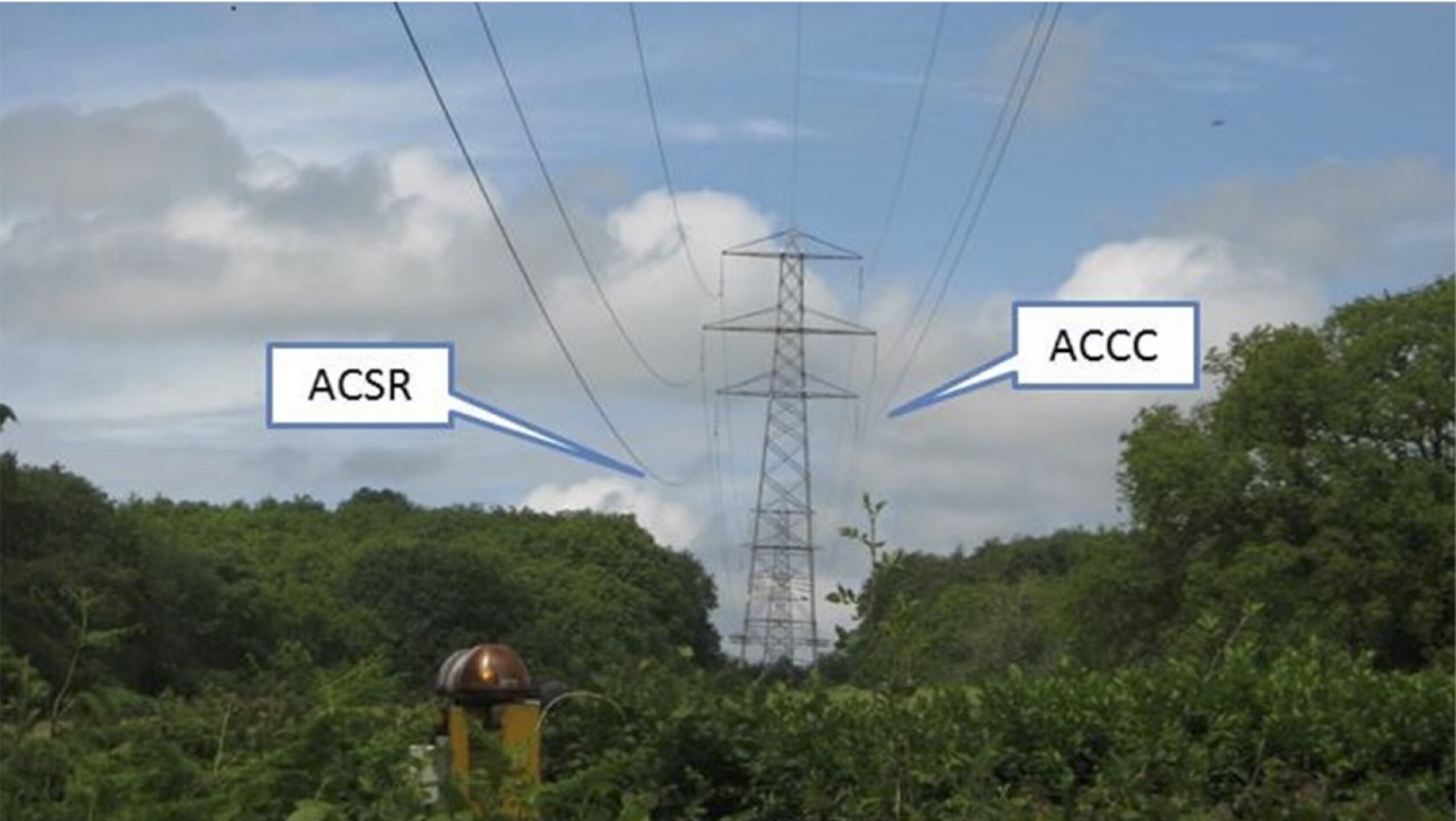

Experienced linemen and project managers know that conductor installation can be very challenging especially when crews are facing rough terrain, accessibility, or weather challenges, or other less than optimal conditions. To help CTC Global’s customers confirm successful installations – even in the most adverse conditions – CTC Global developed the ACCC InfoCore® System.

The patented ACCC InfoCore® System was developed, tested, proven, and commercialized over the course of eight years at a cost of well over ten million dollars. The System has been validated by a number of utilities in the U.S., Europe and Asia, and is now being deployed globally with hundreds of kilometers installed and verified with more than three years of field experience.

The success of CTC Global’s ACCC InfoCore® System can be attributed to a number of factors: Collaboration with key customers; intensive lab work with world-renowned experts; and the development of highly consistent and sophisticated manufacturing methods, are just a few. While optical fiber placement and embedment in the ACCC® Conductor’s composite core is important for many reasons, including accuracy, redundancy and reliability, embedment creates data acquisition challenges which CTC Global skillfully overcame.

Initially, InfoCore® Inspections were performed after the conductor was pulled in and tensioned before dead-ends and splices were completed. The InfoCore® System and modified ACCC® Hardware assemblies now allow linemen to quickly perform inspections after dead-ends and splices are installed. This capability also offers the possibility of future reinspection.

While the ACCC InfoCore® System uses optical fibers strategically embedded in the ACCC® Conductor’s core, the System itself includes devices that allow the composite core to be prepared for linking with a signal sending unit and signal receiver used to check core integrity. Data from the receiver is transferred to a control unit that enables instantaneous verification by personnel on the ground. Data from the control unit is then transferred to a cloud database to document and record the installation’s success.

If you would like to learn more about the ACCC InfoCore® System or learn why more than 250 major utilities have selected ACCC® Conductor for more than 1,100 projects in 65 countries, please reach out to us and we will be happy to provide more information and/or offer you a demonstration at your facility or ours. Please visit www.ctcglobal.com or email [email protected]. You can also read about a number of successful ACCC InfoCore System installations at our Company Blog. Thank You