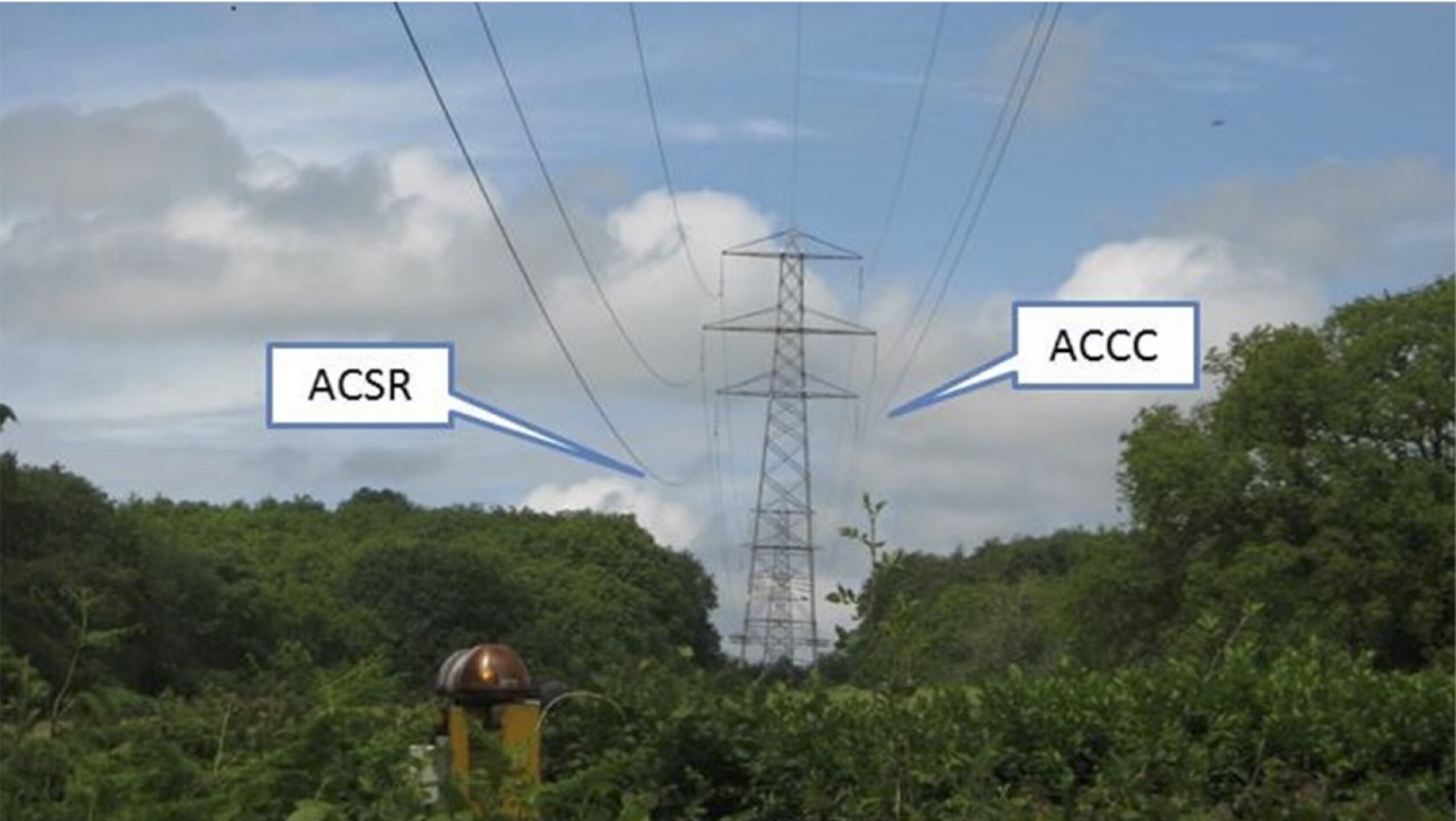

In the past, choosing an overhead transmission conductor was a relatively simple process. Wires were selected to transfer power from a generation source to a load center or substation. While copper conductors are still used for lower voltage distribution lines, most transmission and sub-transmission conductors (20 kV and higher) use aluminum strands wrapped around a steel core, enhancing their strength and allowing for longer spans between towers or poles.

The capacity of bare overhead conductors is influenced not only by the cross-sectional area of the aluminum but also by various weather conditions, including ambient air temperature, solar radiation, wind speed, and other factors.

Transmission engineers must not only select the appropriate conductor size but also design or choose structures capable of supporting the wires’ weight, tensile loads, and sags affected by operating conditions and weather. As conductors carry higher currents, their electrical resistance generates heat, causing them to sag thermally. It is crucial for engineers to consider many factors to prevent conductor sag from violating safe clearances near structures, vegetation, roads, or other objects.

Although the ACCC® Conductor offers improved thermal stability, greater strength, longer spans between structures, increased capacity, and improved efficiency, it typically comes at a slightly higher cost per meter compared to conventional steel-reinforced ACSR or ACSS conductors. The scenario below aims to demonstrate how the higher initial cost of the ACCC® Conductor can be offset quickly, considering the substantial benefits it offers.

The scenario considers a 40-mile 220 kV single-circuit transmission line. Electrical performance calculations follow IEEE 738 Guidelines with the following basic assumptions: Ambient temperature 30° C; Wind speed 2 ft/second; Solar absorptivity and emissivity 0.6; Wind angle 90°.

Here, we compare a 1113 kcmil Finch size ACSR Conductor with the 1447 kcmil Munich size ACCC® Conductor. Both conductors have similar weight and diameters. The load requirement is 1,200 peak amps with a load factor of 50%. ACSR has a maximum ampacity of 1,266 amps at 100°C, while the ACCC® Conductor can handle 2,376 amps at 200°C. At 1,200 amps, ACSR reaches 93°C, while the ACCC® Conductor stays at 75°C. ACSR has a reserve capacity of 66 amps, while ACCC® offers a far greater 1,176 amps.

While it might be possible to choose a smaller and lighter (and less expensive) ACCC® Conductor, the growing demand for electricity makes it more practical to focus on advantages when considering a new transmission line. If we assume that land, permits, structures, and installation costs are equal for either conductor, we can concentrate on the conductor cost alone.

Using ACCC® Conductor in this scenario provides the following benefits:

-A 30% reduction in line losses, equivalent to 14,512 MWh/year or $1,451,220 at $100/MWh.

-A 1.66 MW savings of generation capacity, saving around $1.6 million.

-30-year line loss reduction savings of $43,536,572 at $100/MWh.

-An annual reduction of CO2 emissions by 7,011 metric tons (210,317 MT over 30 years).