To protect businesses and the public, standards and test protocols are frequently developed to help ensure that products and product replications perform as intended and are produced consistently. ASTM International (formerly known as American Society for Testing and Materials), is an international standards organization that develops and publishes technical standards for a wide range of materials, products, systems, and services for virtually every industry. Currently 12,575 ASTM Standards exist to protect Consumers and ensure product quality and consistency.

ASTM Standard B-987-20 “Standard Specification for Carbon Fiber Thermoset Polymer Matrix Composite Core (CFC) for use in Overhead Electrical Conductors” offers a plethora of performance and test protocols that are critical to the performance, integrity and longevity of carbon fiber cores used in overhead electrical conductors that must perform reliably in extremely harsh environmental conditions for decades.

One of the most important components of ASTM B-987-20 is the requirement for a non-conductive galvanic barrier with a minimum thickness specification to prevent galvanic corrosion over the conductor’s anticipated 40+ year service life – as corrosion is one of the leading causes of premature conductor failure – that can lead to broken conductors, power outages, wildfires, and other tragic outcomes.

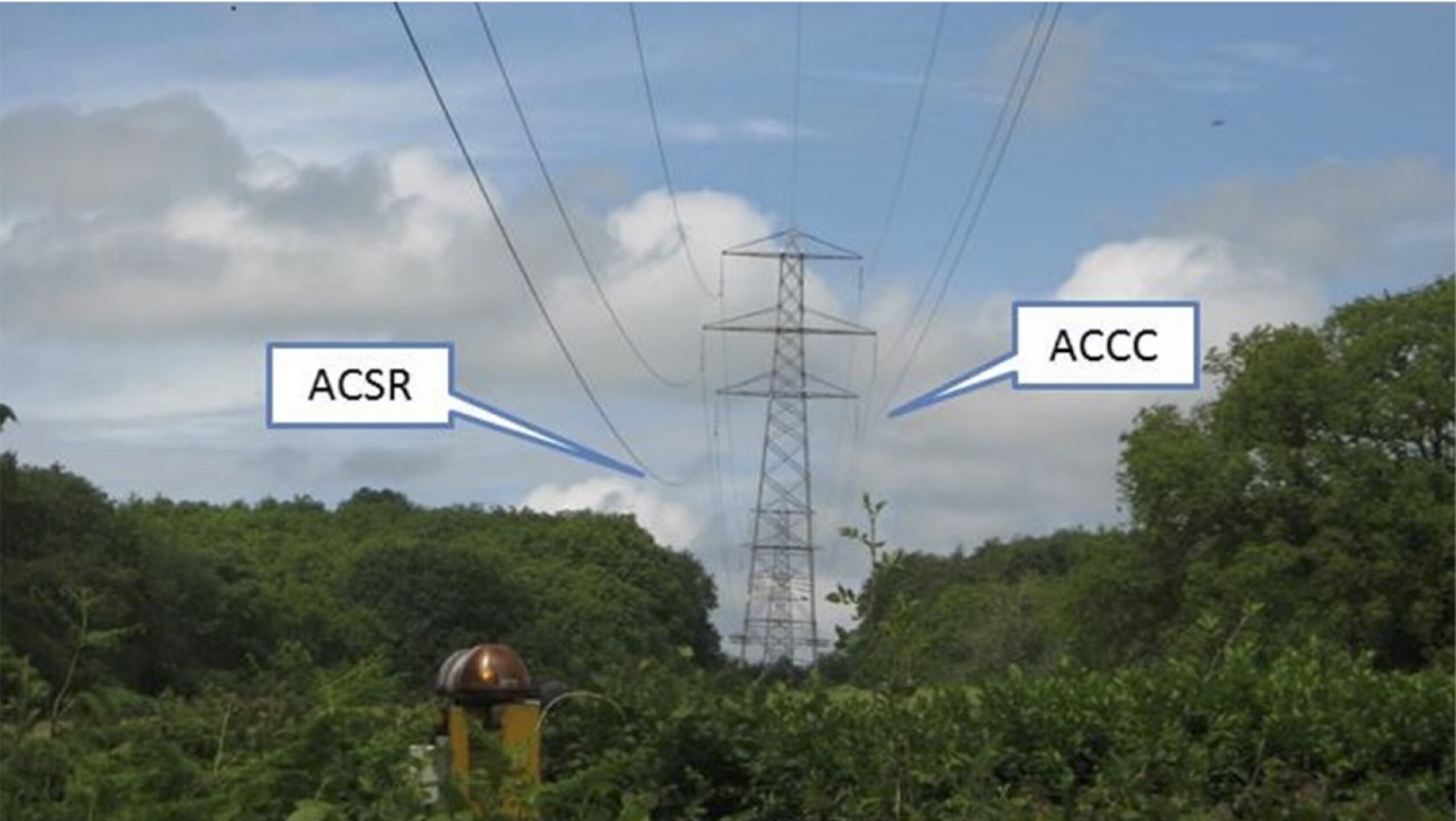

While corrosion of aluminum and steel used in legacy ACSR conductors will occur in wet conditions, which can be exacerbated by salt air, industrial or agricultural pollutants, galvanic corrosion can also occur. Galvanic corrosion is an electrochemical process in which one metal corrodes preferentially (and at an accelerated rate) when in contact with a different type of metal in the presence of an electrolyte, such as water. While steel core wires are often coated with zinc to reduce the rate of galvanic corrosion between the conductor’s core and aluminum strands, the risk of galvanic corrosion with carbon fiber cores is far greater due to their substantial difference in electrode potential as shown in the chart below.

“Carbon fiber and aluminum cannot be allowed to make direct physical contact when water or other electrolyte may be present”

If you are considering carbon fiber core conductors, please be advised that adherence to the established ASTM B-987-20 Standard – and especially its requirement for a robust non-conductive galvanic barrier – can mean the difference between a conductor that lasts many decades in use or one that fails prematurely. If you have any questions, please contact [email protected]