Preface:

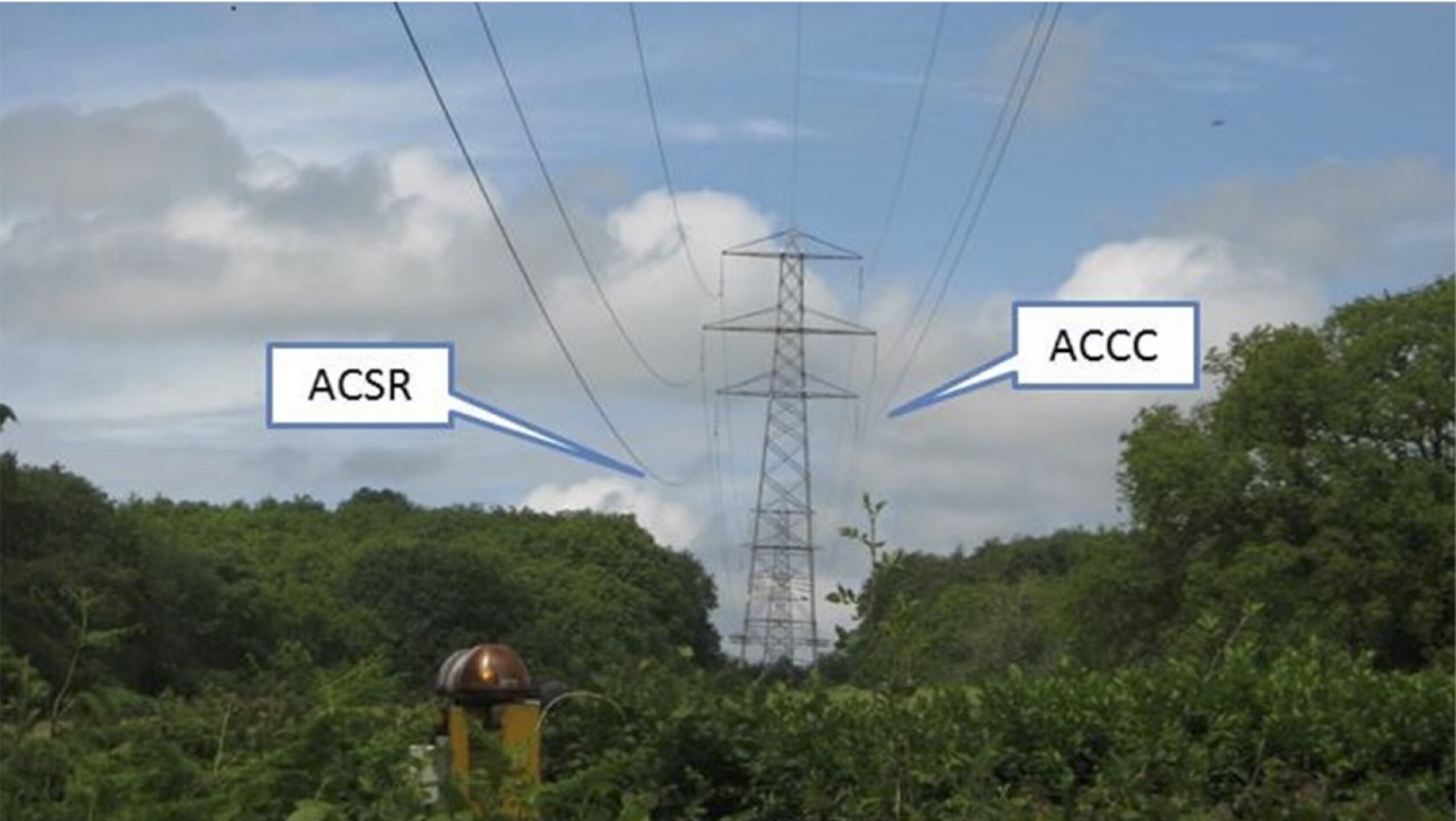

The ACCC® Conductor’s high strength, light weight, and thermally stable composite core – in conjunction with its added aluminum content (~28% more) with no diameter or weight penalty (in any given size) make it ideally suited for a number of transmission and sub-transmission projects in voltages ranging from 11 to 1,100 kV.

Background:

The capacity of a transmission line is limited by the conductor size, thermal operating limitations, safe sag clearances, voltage, environmental conditions, and other factors. Grid constraints or ‘grid congestion’ can occur due to increased demand, limited access to generation assets and/or the lowest cost or cleanest source of generation or planned or unplanned outages. These constraints can impact reliability and resilience and are known to cost utilities and consumers billions of dollars ever year in the U.S. alone.

Reconductoring:

The ACCC® Conductor’s ability to double the capacity of an existing transmission line by simply ‘pulling out the old wire and pulling in the new wire’ make it ideally suited for reconductoring projects. As mentioned, reconductoring can increase capacity, mitigate grid congestion (“bottlenecks”) and improve reliability and resilience – while also providing access to the lowest cost and/or cleanest source of generation. Reconductoring with higher capacity ACCC® Conductor can also ‘future proof’ the grid by allowing increased capacity for future growth.

New Line Applications:

The ACCC® Conductor is being selected for new line projects when life cycle costs, anticipated load growth, and efficiency benefits are considered. Though some transmission developers still target the lowest first cost and choose lower grade, less expensive conventional all aluminum or steel core conductors, many entities – and project financiers – have begun to recognize that the benefits of the ACCC® Conductor greatly outweigh its slightly higher ‘per meter’ cost. The ACCC® Conductor’s improved and documented energy efficiency can reduce transmission line losses by 25 to 40% or more. Lower line losses can reduce fuel consumption, associated GHG / CO2 emissions and free-up generation capacity otherwise wasted. While the cost of a conductor typically represents less than 25% of a new transmission line project’s cost, the added cost of ACCC® Conductor is fairly negligible and, when operating costs and savings are considered, payback times are usually measured in months and benefits can be banked over the life of the conductor. In some cases, depending upon terrain, the ACCC® Conductor’s higher strength and reduced thermal sag can also enable greater spans between fewer and or shorter structures (with smaller foundations) to reduce overall project costs and construction timeframes.

Long Span Applications:

The ACCC® Conductor’s higher strength (about 2X that of steel core conductors), dimensional stability, and outstanding resistance to cyclic load fatigue (that can occur due to wind induced “Aeolian” vibration), make it ideally suited for long span water crossings and mountainous terrains.

Highly Corrosive Environments:

The ACCC® Conductor’s outstanding resistance to corrosion makes it ideally suited for highly corrosive salt air, agricultural, and industrial environments. Agricultural fertilizers, industrial pollutants, and salt air can quickly degrade lower quality aluminum alloys and steel core conductors. While corrosion can be exacerbated by dissimilarities in conductor materials – referred to as galvanic corrosion – the ACCC® Conductor’s carbon fiber core is surrounded by a high strength and toughed fiberglass composite matrix. This adds another degree of protection compared to some of the other composite core technologies recently proposed.

Reliability / Resilience and Grid Hardening Projects:

Projects reviewed by grid operators and public utility commissions are highly scrutinized. Projects, typically envisioned with a number of objectives, are often submitted under the “Reliability and Resilience” heading to accelerate approvals. The term “Grid Hardening” has also been added to objectives list. The ACCC® Conductor’s ability to mitigate excessive thermal sag (and resolve sag infractions) supports reliability objectives and can reduce fire risk. The ACCC® Conductor’s improved sag clearances and thermal stability can also help it survive wildfires caused by lightning strikes or other factors. These aspects, coupled with its high strength and toughness, make it an ideal choice for Reliability, Resilience and Grid Hardening projects. It is also noteworthy that the ACCC® Conductor’s greater capacity can allow grid operators to reroute power around high-risk fire areas to reduce fire risk during dry and high wind conditions.

While it’s not too surprising that many utility engineers still rely on 100 year old conductor technology, and incentive issues still need to be addressed in policy forums, CTC Global’s efforts have led to the successful completion of over 1,100 ACCC® Conductor projects in 65 countries.

Please direct any specific questions to [email protected] Thank you.